Air Venturi G9 high-pressure hand pump.

This report covers:

- What started this series?

- How powerful were antique big bores?

- Back then

- Calling them names

- No one knew

- Hand pumps of antiquity

- Empirical testing

- Early rapper

- Single-stage pump tradeoff

- But wait — there’s more!

- End – for today

Today I start a hopefully long series of reports on hand pumps. I will get to the high pressure hand pumps than can be purchased, but to start laying the groundwork today I want to go all the way back to the first ones.

What started this series?

Reader Elmer Fudd asked several questions about hand pumps yesterday. He said, “Maybe some information on the various hand pumps that are available would be helpful. How does a 3-stage pump work? Are the more expensive hand pumps worth the difference in price? Do the more expensive hand pumps reduce the pumping effort required for higher pressures? What is required to operate and maintain a hand pump properly?”

Reader shootski then chimed in and I knew this was a subject I needed to address again. If one person comments there are usually about 250 people who aren’t registered to comment, but also want to know.

How powerful were antique big bores?

Back in the mid-1990s — the days when I was still writing The Airgun Letter and Airgun Revue magazine — I had a prolonged discussion with Dennis Quackenbush about the performance of the big bore airguns of antiquity. He had just come out with the .375-caliber Brigand that was about to start the airgun world on its modern journey toward big bores, and there was a lot of interest in them.

This report is not about big bores, but the hand pumps that were used to fill them. However, this was where we needed to begin because the first hand pumps were used with these airguns.

Back then

I wondered back then how powerful those old airguns were, and also how they were filled with compressed air. How could anyone fill an antique big bore airgun with air compressed high enough to launch a lead bullet with lethal force? There were no scuba tanks and no shoebox compressors back in those days (1600s-1900s). Indeed, there weren’t many devices that could compress air at all, to say nothing of the relatively high levels that were required by an airgun! And we didn’t even know what levels they were.

Calling them names

They didn’t even call them hand pumps back in the 1600s. They were called condensing syringes, and compressed air was called condensed wind. The terminology had yet to be established.

No one knew

It seems strange today with all that we know about big bore airguns, but as recently as 1997 almost nobody knew how fast these old guns shot or what sort of pressure they used. I read all sorts of guesstimates of velocities up to 1,000 f.p.s. for the antique big bores.

Eventually splatology (the determination of terminal velocity by the shape of a deformed lead ball after it hits a hard surface) was developed by Gary Barnes, but Barnes came to the party in the late 1990s, and these questions were being asked several years earlier. Elmer Fudd and anyone else who wants to know — I would follow that link to Splatology and read that report. It tells you a lot about big bore airguns of antiquity.

Hand pumps of antiquity

One thing we did know about the vintage big bores, is what their hand pumps looked like. Many of them survived along with the guns, and they are usually in better condition than the guns themselves.

I have examined several antique hand pumps at airgun shows. The ones I saw always operated very smoothly, like their pistons had been lapped. I saw the insides of two pumps and neither of them had a piston seal. They had a flat iron piston head on the end of the pump rod. A light to medium weight oil (like 3 in 1) was squirted into the pump before it was put into operation. Oil on the compression chamber walls did all the sealing — similar to how it works in an automobile engine.

This is an antique hand pump. The reservoir — a ball in this case — is screwed onto the top of the pump between the handles (left). The operator stands on the pump base (right) and pumps up and down several hundred times to fill the ball. Photo courtesy of Larry Hannusch.

I have read several accounts of hand pumps that have leather piston seals. They were either a single leather seal covering the end of the piston, or they were a stack of leather washers fastened together at the end of the piston. These presumably work the same way as the plain metal pistons, plus the leather helps keep oil on the walls of the compression chamber. I only know about the stacked washer type from reading Air Guns by Eldon Wolff. He admits that the leather washer type is much rarer than the plain piston type. But how effective were they? What sort of pressure could they generate?

Empirical testing

I asked Dennis how much pressure a common single stage hand pump could generate. He had been making replica hand pumps for vintage big bore guns for several years. Dennis’ pumps are true to the old designs, except that they use synthetic pump seals. He suggested that we test some pumps and find out.

Before we conducted the tests, it seemed to both of us that neither vintage pump design (plain piston or one with a leather seal) could equal one with a modern synthetic seal. Whatever pressure could be achieved with a modern replica would probably represent the absolute maximum for any vintage pump of the same physical specifications. That turned out to be an incorrect assumption.

Early rapper

We both agreed that the practical limit to the force that could be applied had to be the weight of the person doing the pumping. These early pumps had no mechanical advantage beyond that which is inherent in a single-stage mechanism. Although it would be possible to generate more force than one’s weight by pulling the base of the pump toward oneself, it isn’t practical — and would be very hard to do on a continuing basis. Jumping on the pump handle, however, is actually a method that was used sometimes. It was called rapping, but it’s very hard on the hands, wrists and arm joints and you can’t do it very long.

Single-stage pump tradeoff

Okay — remember when Mr. Conners, your 8th-grade math teacher, told you that one day you would need to know geometry? Today is that day. A single-stage air pump works by means of a piston that moves up and down inside a cylinder. It admits air into the compression chamber at the top of the stroke by means of a one-way inlet valve and forces it out an exhaust valve or port as the piston moves down. The larger the diameter of the piston, the more air is inside the compression chamber to be compressed. The longer the piston stroke, the more volume inside the compression chamber, as well. Those two things determine the amount of air that gets compressed — the diameter of the piston/compression chamber and the length of the piston stroke.

As the air is compressed, its pressure rises. This is felt as resistance on the pump handle. The higher the compression, the greater the resistance. Small diameter piston = lower resistance. Larger diameter piston = greater resistance. You can compress more air with a large-diameter pump piston, but the resistance will build up faster. And a smaller-diameter pump piston lets you compress air to higher pressure, though less air is compressed with each stroke.

The question is, what pressure do you want to compress the air to and the answer brings““` another question — how much do you weigh? Because when you reach your weight, it isn’t easy to pump any more.

But wait — there’s more!

Hold on, B.B. You said that the length of the pump stroke also determines how much air gets compressed. Couldn’t the pump have a very small piston with a really long pump stroke, and therefore compress a lot of air to a high pressure? Why, yes it could! Mr. Conners would be proud of you.

So — how tall are you? You see, when the pump stroke gets longer than you can conveniently pump, all the fancy science stuff doesn’t matter. A hand pump with a 5-foot (1.5-meter) pump stroke isn’t very useful, is it? Not only is it hard to carry, it’s also difficult to operate when the pump handle comes up over your head on the up stroke! You need that handle to be low enough that you can lean on it on the down stroke. It really matters when the air pressure/resistance rises beyond a certain point. That point is determined by your height and weight.

Mechanical advantage is possible, and some vintage pumps use it, but they’re rare compared to the bulk of the pumps we know about. I have never seen one. The single-stage manual pump I have described today is the most common design encountered in vintage airgun equipment.

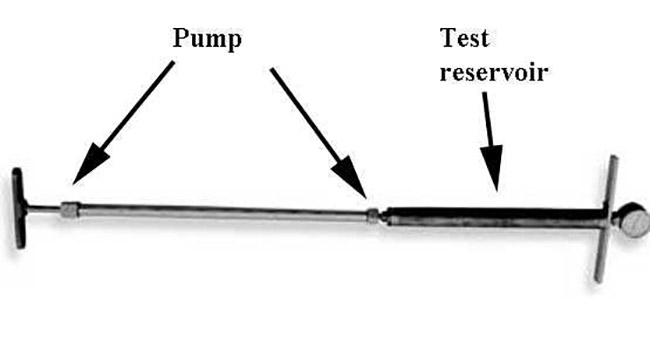

Dennis saw where I wanted to go with this experiment, and he took up the challenge enthusiastically. He used two different vintage-type pumps of his own manufacture, plus the modern Axsor pump to check efficiency. He also made a 9 cubic-inch air reservoir with a built-in pressure gauge.

The test fixture Quackenbush made to ascertain single-stage hand pump efficiency. The pump that’s attached to the test reservoir in this photo has a 5/8″ piston head. The reservoir holds 9 cubic inches (about 147.5 cc) of air. With this setup the operator stands on the pump handle (left) and pumps the air reservoir up and down (right).

End – for today

I’m going to end the report here, but know there is much, much more to come. Elmer Fudd asked some very good questions and I want to take my time to answer them as fully as I can.

B.B.

You have a great way to determine the force required to cock an airgun.

Is there a similar way to determine the force required to pump up an airgun reservoir to 3000psi?

-Yogi

PS do larger air chambers on a PCP need different force than a smaller one?

Yogi,

The last stroke of the pump will be the one that causes it to reach 3000 psi. or Pounds (which is a measurement for force) per Square Inch (which is the area that that force is being applied to). To find the force required to push down that last stroke of the pump, provided we’re still talking about a single stage pump, you simply multiply the 3000 psi by the area of the face of the pump’s piston. If you know the diameter of the piston you can find its area by multiplying the Square of the Diameter of the piston by the constant .7854 (The area of a 1 inch diameter circle is .7854 inch) or DxDx.7854. Once you have that number you can do the aforementioned multiplication. Or…..you can put the foot of your pump on a scale and read it as you put in the last stroke of air from the pump. Of course that won’t work in this case because even a 1 inch diameter piston would require 2356 pounds of downward force to reach 3000psi. That is why it takes a multistage pump to reach those pressures. With a multistage pump you CAN simple put it on a bathroom scale as you put in the last puff of air. (Just the pump, not your feet)

Half

Half,

So if your weight is 200 lbs you need a piston of .0667 Sq inches to get to 3000psi with just your weight and no leverage.

Benji-Don,

my thoughts are, unless the transfer section from pump to reservoir equals the size of the pump piston tube, then, would one not have to include the smallest transfer section in one’s consideration? I imagine that would likely be the inside diameter of the valve.

I believe that the tighter the hole the longer it takes to push the same volume of air through but greater pressure can be achieved. 🙂

hihihi,

Not really. The transfer orifice will impact how long it takes to transfer the air into the gun, but the air will move through it until the pressure on one side is equal to the pressure on the other side of it.

The pressure on the PUMP side of the orifice WILL rise above the final pressure temporarily, but that is necessary to get flow of any fluid through an orfice. It will always flow from the higher pressure to the lower pressure and will do so until the two pressures equalize, then the flow will stop.

A smaller diameter “transfer section”, as you call it, will take longer to equalize, generate more heat and create a higher temporary back pressure in the PUMP that may be noticed as additional effort for the guy doing the pumping, if he “horses” it rather than applying the force only as fast as needs be to move the piston down. It won’t result in a higher pressure in the reservoir though.

Half

halfstep,

ah, ok.

What I meant then, is, that the point of highest pressure here, is where the flow of air is restricted the most. Imagine a jet of air, pinching the end of a garden hose, etc… 🙂

Benji-Don

That might be true if you stand on the pump handle. Otherwise you might need to be 400 pounds, overall, to be able to apply 200 pounds from the waist up or have an even smaller piston area. The piston you’re describing would be about .29″ in diameter, BTW and would require a lot of stroking to build up to that final pressure, again explaining why the multi stage pump is the only practical solution.

Half

Half,

So a 100 pound person would need one half the piston head area as a 200 pound person and twice as many strokes for the same volume of air. No wonder the 100 pound folks are in better shape than me.

As a side note my Seneca Aspen is still holding air and the pump is working fine. I pump it slow, pause between pumps and keep it lubed with Crosman silicone chamber oil. It is a great value for the cost. Many folks have had problems with the pump reliability, I expect it is from over heating (pumping too fast with no pause between pumps) and horsing the pump (applying excessive force on the pump handle).

Don

Benji-Don,

You got it B-D! Always remember, though, that it’s the AREA of the piston, not the DIAMETER of the piston. As the diameter is halved, the area will be reduced by a factor of 4, so will the force now required and the number of strokes will quadruple.

Half

That would, if my math is right, mean a piston of just a touch over 1/4 inch (9.32/32). If you want less force to be needed, just make a smaller piston and bore.

Half & BB

Half, you must have been a gifted teacher of science. Thanks for this explanation. LOL reading the last sentence!

BB, count me among those enjoying this topic. I’m learning stuff and I’m also a history buff. I don’t know if this series will get into how the early big bore airguns got so many good shots. I’m guessing it was very large reservoirs (like an auto fitted with a 30 gallon gas tank).

Deck

If Yogi is asking for info on hand pumps what comes next? A change of tide towards PCPs? Where is the world going to?

Humor aside you should not be worried. If the 3622 needs a 5 lbs accessory pump and two strokes for every 16fpe shot then any springer in the same power level seems much much better choice in terms of efficiency and ease of use. And as you very well know there are many good ones even in the price range of an entry level pcp with a pump.

Bill,

There are several problems with sproingers, no matter what the cost. Very few sproingers will achieve better than 2 MOA.

Also, there is the matter of multi directional recoil and movement. Some of this is eliminated with gas sproings, but not all.

You must also factor in cocking effort. With some of the more powerful sproingers, it is easier to pull back on the bow of Hercules. A longer barrel will help with the leverage of cocking, but the longer the barrel, the longer your arms must be.

Most sproingers only achieve about 1000 PSI. This in part limits the size of the projectile, its velocity and its range. Also with sproingers a barrel length over about eight inches has no effect on the increase of these factors, except maybe to reduce them.

PCPs can be far more accurate and of much greater range. They are capable of hurling much larger projectiles than sproingers.

Do not get me wrong. I have several sproingers and enjoy them very much. I also have PCPs. Each has its place.

Agreed RR, each has its place! Like you, I enjoy them all.

For those new to airgunning, I just wanted to mention that the very accurate sproingers are low velocity (usually sub 600 fps) .177 caliber target rifles (like the Feinwerkbau 300) designed to shoot light pellets.

Accurate “hunting power” springers (like the Air Arms TX200 and many of the Weihrauchs) are available.

I’ve never seen a “Magnum” (1000 fps plus) springer that could consistently hit a 1″ spinner much beyond 10 yards. Maybe they exist.

Hank

Vana2,

Hank I’m glad you chose a 1″ spinner and ONLY ten yards!

There are a few still being built and one model is no longer in production.

shootski

Hank,

Very likely the cost would be prohibitive for such a magnum sproinger. Shootski has a couple that are almost magnums and on the assumption you can find one, the cost is prohibitive.

RidgeRunner,

erm, only yesterday, MMCM13 pointed out the same airgun for sale that shootski used, and to prove a point, the results of which he shared above. Yes, a SigSauer ASP20 in .22″ calibre.

I checked and it was offered for a mere $239.99 = what a bargain, at least in my eyes!

What seems like a “… prohibitive cost…” to you, is often just a price to pay for people like me. I see a difference in priorities that limits me less. 🙂

I do hope it was you who bought it… ! 🙂

I was not quick enough. I would have for that price. Recently on eBay I saw one offered for $900, I think.

3hi,

I may actually have seen it, but it is not what I am looking for. I have spent $1700 for a NIB (new in box) .357 RAW air rifle at the NC show, because it was what I wanted at the time. She was a boringly accurate air rifle at 100 yards. She now lives somewhere else.

There are some airguns that at no matter what the price, I am not interested in them. If you want my attention, offer me a shooting condition Quakenbush bb gun at that price. An original shooting condition “Daisy” would be nice.

RidgeRunner,

come on, you said, “… on the assumption you can find one, the cost is prohibitive.”

We humans all make mistakes and that was one of yours! 🙂

Bill,

you make an interesting point with “… efficiency and ease of use…” between two types of airgun power.

I believe and hope the precharged pneumatics will one day beat the spring powered airguns in this respect. But first, the onboard handpump has to be made reliable.

Finally, and especially for people with limited physical strength, I would recommend airguns powered by the little carbon dioxyde bottles. 🙂

edit: just as I posted the above, it occurred to me that, for single shot airguns, the single stroke pneumatics, already better the spring powered versions, at least over low power distances. My hope is for the reliable onboard pump for multishot reservoirs… 🙂

hihihi,

See my reply to halfstep above about my Seneca Aspen it is a pcp that has an onboard pump and a small reservoir.

https://www.pyramydair.com/blog/2019/02/air-venturi-seneca-aspen-25-caliber-precharged-pneumatic-air-rifle-part-4/

Benji-Don,

yes that’s it! Exactly the kind of airgun I am hoping will become so reliable as to seriously rival the performance of any springer. 🙂

I am happy that yours is still in full working order. 🙂

Amongst us commenters there is one other who has such a type of airgun. His is the FX branded version, called Independence, which has already needed a seals renewal and, unfortunately, it’s onboard pump has failed.

What a shame this onboard pump system has yet to become more popular and further developed, eh. 🙂

BB,

I’m one of “the fifty,” that is, the registered users who can comment, but didn’t, yet now agrees that we are just as interested as Elmer Fudd and shootski in this topic…looks like it will be a great series. 😉

Blessings to you,

dave

Dave,

The number of registered users is much larger than fifty, but they don’t comment that much — or ever!

Glad you are enjoying this. I knew that a lot of people would be interested in this report so I have planned to make it a big one.

BB

B.B.

I’m one of those who also doesn’t comment much. Fortunately I learned not to act or speak like I know more than I actually do which is why I don’t comment much.

Like others I’m looking forward to this series on hand pumps, although I’m not likely to buy a pump and budget level PCP because I have enough airguns already.

I shoot exclusively in my basement at a max distance of 10 meters. From what I read in your blog and airgun reviews, pretty much all PCPs shoot at 1000 fps or more with a considerable high noise level that might be too much for indoor use even with a compensator.

There once was an Air Arms T200 Sporter (I think that was the name) that was a 10 meter PCP at approximately 600 fps shot velocity, but I didn’t want to pay the high price for it and a compressor.

cstoehr, AirForce, Crosman, and Daisy all make $1,000 or less 10-meter air rifles now. Mostly for JROTC, 4-H, and BOY Scouts, they’re adjustable enough for us adults.

“I knew that a lot of people would be interested in this report so I have planned to make it a big one.”

Awesome; love it!; thank you. 🙂

Yet again, the Godfather gives a Master’s class to his disciples!

Tom,

I’m really going to be interested in the outcome of the single stage pump because those are what powers multi stroke pump airguns after all. Based on a local experiment I believe you will get around 800-900 psi maximum.

Siraniko

Siraniko,

We shall see — together. 😉

BB

This is going to be a very interesting series , looking forward to the rest of it. I have three “china” pumps , one works, one needs rebuilding and one is still new in the box. I bought these several years back when they could be had for less than $ 50.00. The new wave of affordable electric high pressure pumps have made me lazy and the hand pumps get no love . I have two GX pumps and they make life much easier, I do need to use the hand pumps occasionally just to stay familiar and to be sure I always have a functioning one.

SSC,

Thanks for posting this about your experiences with those Wang Po Industries hand pumps. I was just about to order one, but now I may have to wait a bit before I do such.

I have an old AirForce hand pump, but it needs rebuilding and I just cannot find the “round tuit” for doing such.

SSC,

I’m fairly new to modern airguns, having ‘rediscovered’ them in my later years — although I was mighty familiar with them as a youngster!

I have a couple break barrels and a few various types of pistols (C02, single-stroke pump), but I haven’t had much interest in PCPs because of 1) their price and 2) the electric pumps cost as much or more than the guns! But the new Crosman 3622 addresses the first issue and I am sure other manufacturers will move to compete with that gun, which is great. And maybe I could deal effectively with a handpump. That is why this article by BB is so timely. I agree with you that this is going to be an interesting series and I too am looking forward to the rest.

BB might have some clairvoyant skills.

MiTurn

If I were to use the sights I would have to replace the front sight with the metal ones that Crosman sells for the 20 and 17 series C02 pistols. I have one 2240 that still has the plastic front sight but I glued it to the barrel with Two ton epoxy after sighting in and making witness marks. The factory front sight will move and that can be helpful for adjusting windage . The metal front sights have a set screw to fix them to the barrel. The upgrade that Pyramid offers for a steel receiver and keeping your warranty cannot be beat.

The biggest lesson I learned about hand pumps is to go SLOW. Pump slow and deliberate, and take breaks to let the pump and you cool down. Also my rule of thumb is to stop after every 1000 .lb increase in pressure and take a break. I burned up the pump that came with my Umarex Origin (first PCP) in short order by pumping too fast and for too long an interval.

Thank you vewy much BB! You are explaining everything exceptionally well (as usual). Learning these things is interesting and valuable. We are blessed.

Elmer,

Thank you for asking these questions. Us old, fat, balding geezers sometimes forget some of this stuff over the years and there are a bunch of newbies who could most definitely benefit from knowing this information.

“Us old, fat, balding geezers…”

RR,

I resemble that remark, although I like to think of myself as streamlined and robust.

MiTurn

I am about as streamlined as a very large beach ball.

BB,

THANKYOU! THANKYOU! THANKYOU! THANKYOU!

I am at present in search of another hand pump. I recently gave my Hill to my grandson to use and need another one to replace it at RRHFWA. Although I have a large AV compressor, I like to keep an hand pump handy to use in an “emergency” or sometimes just to fill the “low pressure” PCPs (3000 PSI or less).

This is a little note for Elmer.

The more stages, the better. It will take longer, but will be easier to pump.

RR,

Soooo a five stage pump will be easier to pump to 3000psi than a 3 stage pump. But it will take more pumps to get there. Got it.

Would a 5 stage pump be able to go to a higher psi (6000 7000)? Just curious.

rk,

Not RR but at some point the seals will no longer hold that pressure or they will have so much friction that it stops the pumping action.

As i replied to Elmer Fudd for the benefit of everyone: HEAT kills hand pumps the Physics (friction and adiabatic) of that much pressure will kill pumps very quickly.

Ultra High Pressure-3,600 (250 BAR) psi air is bad enough but pales when compared to the hyper pressures you are asking about. Those terms i used are NOT hyperbole and for good reason!

I cannot say this often enough.

Be very careful with those extreme pressures!

shootski

I settled on 200 BAR max fill and tunes my PCP rifles , have not looked back. I figure it is easier on the manual pump,electric pump, the rifles and myself. All fill to 3000 PSI but some are tuned for shot count and some are tuned for sickem.

rk,

Do you happen to know where I can find a five stage pump? As for pumping up that high, wow. I think I will head in the other direction.

RR

Fat fingers … small keyboard. Meant 4 stage pump.

But as Shootski brought up, if you could get the seals to hold, would more stages in a pump mean higher psi be possible with less down pressure on the handle?

rk,

I myself do not know of a 4-stage pump either. Is such available, why not.

The point shootski is trying to make is that the higher the PSI to which you are filling an airgun, the harder it is to achieve said pressure. In any pump, electric, hand, etcetera, each stroke will have a diminishing quantity of return when you have more stages. On the assumption that the seals will hold no matter what the pressure, each additional stage will be able to compress a smaller volume to achieve a higher pressure.

Put another way, for a hand pump to achieve the higher pressures that the latest and greatest airguns desire these days, it will take far more pump strokes to reach these higher pressures, but less effort per stroke to do such, the more stages the hand pump has.

My old AirForce hand pump took a considerable effort on my part to reach 3000 PSI than my Hill did, but the Hill took more strokes. I am in the market for a new hand pump to replace my Hill. I have an AV compressor, but it would still be nice to have a decent hand pump as a backup.

RR, just call up PA sales department and tell them you are looking for a condensing syringe for your condensed wind pellet guns… 😉

Elmer,

They would probably not understand that at all. Once upon a time they might have been someone around there that understood that, but I think they are more familiar with crossbows these days.

Here goes again – Word Press got FM and he did not copy-and-paste. #$*&%! – that keeps it FF – Family Friendly. As was “saying” before being rudely awakened by this annoying Glitch, hope the series will address pump maintenance, troubleshooting and repair at some point. But, no rush BB. Right now have a Hatsan hand-pump with a non-functioning gauge; have found some YouTubes on rebuilding pumps and minor troubleshooting, but nothing dealing specifically with gauges – need the proverbial Round Tooit and to just dive into messing with the problem. At least the pump works well. Probably should pick up another for backup.

As for pumping-force limitations imposed by body weight, the flyweight types might consider putting on something “weighty,” such as a backpack stuffed with books, to generate more downforce when pumping. It would be good exercise too. It is also just likely another of FM’s Looney Tunes-type ideas and best ignored. That’s all, folks!

FawltyManuel,

hehe, “… Looney Tunes-type ideas…”, erm : I suggest those ballasting books to be comic books, for doesn’t every picture weigh the equivalent of a thousand words? Now, if that doesn’t deserve an eye-rolling groan… ! 🙂

Handpump maintenance? Surely that’s exactly the same as for the precharged pneumatic gun, ie non-combusting silicone lubricants. Oil for the seals and grease for areas of friction.

Oh yeah, those pumps that include an air drier, well, their dessicant wants periodic renewal too.

Job done! 🙂

Gunfun included some good maintenance documentation and spare O-rings with the pump he so generously donated. Have done some of that maintenance and lubrication and the pump still works well. There are some good YouTube videos on the subject, including rebuilding. Going to pursue replacing the gauge because the pump is a decent one and still does the job.

FawltyManuel,

As far as faulty gauges go the safest way is to replace the broken gauge with a new one as far as I’m concerned. Even if you do manage to zero the gauge how sure are you of it’s calibration?

With regards to increasing the force available to flyweights there is a tool called the lever which has been in use for quite some time. Imagine a seesaw and place one pump on one side and the operator on the other. Better yet a pump on either side and youngsters enjoying themselves while pumping air for you.

Siraniko

Thanks for that – had been thinking along those lines anyway and will be looking for a replacement gauge.

That lever sounds like a good idea for the day FM starts running out of steam – or air. 🙂

B.B.,

Thank’s

shootski

B.B.,

I hope you provide pump strokes vs pressure in the 9 cubic inch reservoir Dennis made for the tests. I want to compare the results with my multi-pump spreadsheet calculator. If I find a roundtuit I will try to publish the results before your part 2 report. So I can’t cheat. I will have to guess at the dead space though.

P.S. I just remembered I need the length of the pump stroke.

My remembered kicked in, doesn’t happen often. I have the stroke.