The BAM B15 breakbarrel air rifle.

This report covers:

- Rebuild!

- Unsprung

- Piston seal

- A win!

- Came apart easily

- Summary

- Something new

Today I start a report on rebuilding the BAM B15 breakbarrel spring-piston air rifle. I was inspired to do this when I wrote the report on Little springers early last December. I discovered then that my little BAM B15 will not fire a pellet.

The B15 would not fire a pellet. Yes the breech seal looks bad, so I’m working on a replacement for it, too.

Rebuild!

I didn’t know why the powerplant was so weak so I needed to take a look. Well today, campers, I found my round tuit! We’re gonna take this thing apart and have a look inside! This report will mostly be photos of the work as it progressed.

With the stock off I can see the B15 is completely dry. So I need to lubricate it as I repair whatever is wrong.

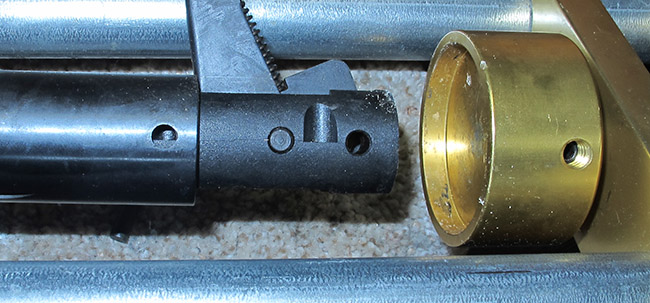

The barreled action is in the mainspring compressor. I see two things are needed to take the action apart—the bushing that I have started to unscrew and one pin at the rear of the spring tube.

Unsprung

The mainspring is not under a lot of preload. The end cap backed out perhaps 1.5 inches/3.81 cm before all tension was off. The mainspring then came out and I saw that everything inside was dry as a bone.

The mainspring is fully relaxed in this photo.

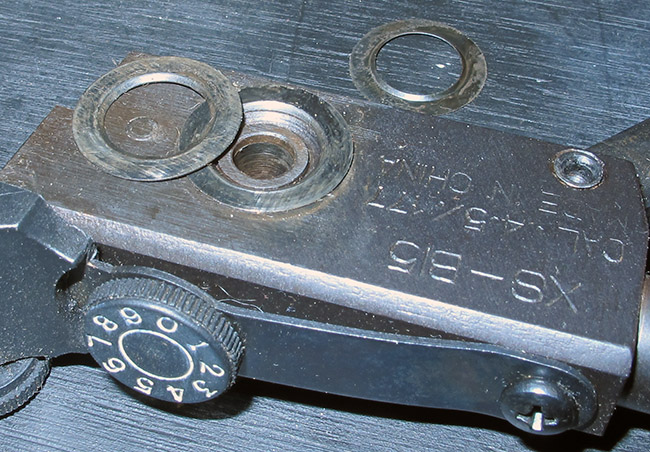

To remove the piston the barrel has to be disconnected from the spring tube. That allows you to move the cocking lever to the place where it pops out of the spring tube, freeing the piston. The B15 has a single pivot bolt that’s held in place with a small screw on the periphery of its head.

The barrel pivot bolt is held in by a screw on the edge of its head. Notice the scalloped cuts that the second bolt head fits into. This is quality work!

Like an FWB 124 the BAM B15 has washers on both sides of the base block.

This rifle is made better than many spring-piston airguns made today. Everything is finely machined and the fit seems flawless. I’m quite impressed by the quality. Only the metal finish is less than that found on the top airguns.

Piston seal

And when the piston came out I saw the reason for the low power. The piston seal is toast!

The B15 piston seal is completely gone.

When I saw that seal I wondered how I would replace it. Would I make a leather piston seal the way I have in the past, or would I source a new seal from somewhere?

HOLD THE PHONE! Don’t I have a leather piston seal on the table next to my desk? As I recall it looks similar in size to this one. Could I make it fit? And first — can I even find it? If it’s like everything else in my messy office it was there right up to the time I needed it and then it went away. But not this time. It was still there and — glory hallelujah, it seems to have been made for a BAM B15!!!

The new leather piston seal that’s been laying around my office is one made for a BAM B15!

A win!

I don’t often win like this, but today I did. I will clean and lubricate the rifle in the next installment and then testing will begin.

Came apart easily

I have to admit, this little springer came apart quite easily today. No screw slots were mangled and all the screws came out right away. As dry as it was I didn’t expect that, but it did. It helped that I had that Vessel screwdriver with multiple bits.

Summary

Thanks to the high quality of the build, this BAM B15 breakbarrel springer will soon be ready to be tested. I don’t know if all B15s are as nice as this one, but if they are it’s an air rifle to watch for!

Something new

Readers, this will be the last week in which I publish five new reports. Starting next Monday I will post new reports on Monday, Wednesday and Friday. Pyramyd AIR is giving me time to do more testing and research for this blog and for other articles I’ll be writing. I’ll also have more time to spend on my You Tube channel.

In discussions with Pyramyd AIR, we established that I can write about firearms as well as airguns, so look for that to happen.

With the reduced numbers of postings I will limit the guest blog spots to one per month, so I’m going to have to be very selective about what that content is.

I know this is sudden and I hope it doesn’t disturb you too much. Look at it this way—I will now have more time to do the things I have always wanted to do. It’s a blessing for me and I will try my hardest to bless all of you as well!

Tom,

Three reports a week is still a lot considering everything you do to make a single one. Then again you ain’t no spring chicken.

Honestly I believe there are some Chinese gems in the rough out there, especially those more recently manufactured. They just need some (or a lot of) finishing to bring out the best in them. Of course most have been destined to be door stops because one expects accuracy and power right out of the store which one will not get most of the time.

Siraniko

Look at all the great budget PCPs; most are SnowPeak products.

OhioPlinker,

So they are. PCPs are relatively easy to manufacture and shoot with accuracy. Spring pistons though simple and cheap are more difficult to handle accurately for a beginner.

Siraniko

Life certainly has its ways. Tom I wish you all the best with everything you do. Most of us will miss the Tuesday and Thursday meetings after all these years.

Anyway, I found it very interesting that this small and cheap airgun from China is so quality made. Even RR might looks at it with some sympathy…

Indeed.

Sounds perfect for you. I was wondering how long you could go on. I know working at something you love doing makes life really enjoyable, but we all need to slow down some eventually. I retired 15 years ago and now I wonder how I managed to find time to work for a living.

My QB-25 only needed to be cleaned and have all the loose stock screws tightened to transform it.

B.B.

Whatever happened to your bird feeder protection rifle?

I believe you would be shooting from an upstairs window.

-Y

Yogi,

You’re remembering my pest elimination rifle. I live in a one-story house and there is no bird feeder. I was trying to protect Swallows in their nests from Mocking Birds. And I don’t know whether I wrote this or not, but I later discovered that cats were the predators and not other birds.

I still have the rifle, but with just three reports a week I now have to be very selective about what I write.

BB

Thanks,

-Y

BB,

What is your Youtube channel? Or a link to it? I’m always interested in learning from what you and others here have to say.

Mike

Mike,

https://www.youtube.com/@airguntomgaylord

BB

Thanks,

I subscribed while I was there.

Mike

BB,

As Bill points out, I really am impressed with the quality exhibited here with this air rifle. This particular air rifle is most definitely worth a rebuild. I may have to keep my eyes out for one of these.

Now we will likely be seeing more about E bikes, crossbows and powder burners. I had noticed more and more that PAIR was moving away from airguns and more toward other stuff. I guess it was bound to happen sooner or later.

BB

Hope PA isn’t expecting you to report on crossbows. So far that has been done by someone else and shows up here as additional reports. Nothing against crossbows and archery except they aren’t suitable for my neighborhood. Powder burners are fine due to my life long hobby and interest.

Glad to hear you will be getting some more time. Will you be expected to only report on current items PA sells? If so I will be spending more time in archives.

Deck

Deck,

I still have free rein on what I report.

BB

Tom, such being the case I would really love to read your report on the Evanix Rex! Having that deep bond with the Airforce series of guns you would be the best person for an honest test.

And my suggestion for reviewing the Hatsan Velox and/or Evanix Viper is still pending.

Bill,

We shall see.

BB

About time you got an extra dose of time for your other interests, B.B. Ole FM is still mighty impressed by your energy level; feel free to share some. Will be a subscriber to your YouTube channel.

Nice things worked out with this B15; even FM might be able to rebuild it with his caveman skills. Still, will stick with the HW family for the foreseeable future, when it comes to “sproingers.” Maybe a TX will join the family in FL down the road.

Congratulations Tom, I appears that you are getting what you want. I always look forward to seeing these blog reports. The Carly Simon song “Anticipation” came to mind when I thought about what it will be like starting next week. And that’s not a bad thing.

🙂

I noticed a video or two on your YouTube channel regarding the Endosnake device. A search here showed one report on it. But the comments were missing; and the link to the comments doesn’t do anything. Anyway, is that product something that you think is good for us to consider. I have been thinking about getting a borescope. The one that most people seem to like would only work for .22 caliber and above. It seems like one that works for .177 would be more suitable for us airgun enthusiasts.

Elmer,

I think an endoscope is a good idea. Not sure this is the right one.

BB

Thanks!

Elmer Fudd,

Teslong thus far only makes borescopes down to .22 caliber. They are good enough especially for the price.

For .177 caliber you are going to pay a premium.

https://www.hawkeyeborescopes.com/applications/precision-shooting/

Is a reliable source for borescopes.

They have a free trial program going at this time.

SHOT Show special till end of the month – US$200.00.

Buy once cry once,

shootski

Thanks shootski, I was looking at the Teslong brand. I think I will get one and just do what I can without one for the .177 caliber guns for the time being.

An endoscope small enough to go through a transfer port would be ideal for airguns. But, I don’t see endoscopes that small for sale. I know they exist in the medical industry. My ENT doctor put a endoscope up through my nose to look at the backside of my ear drum. That was kind of weird.

That’s interesting about the eardrum David. I have had my sinuses viewed with one not very long ago. Never thought about looking at the inside of the eardrum before.

FM,

The TX200 is the only air rifle I own that makes me think about getting some soft white gloves to handle it.

It’s a real beauty. Mirrored blue finish. I don’t think anybody would ever regret getting one, but you might regret not getting it sooner.

Thanks for that, Bob M – regret would come into play if it suddenly were made from Unobtainium. 😉

BB,

This rebuild looks like it will be a good one. It’s great when the quality of the airgun is better than you expect; it gives you more in return. It will be a sweet shooter when you’re done!

Wishing you good fortune in your change in schedule and concentration. Please enjoy, we will stay tuned.

Regards,

Will

Of course, I am being totally selfish. Whah! *snif*snif*

It is about time you started to wean us and do what you want for a change.

RR I know, me too. I have a little bit of a quiver lip over BB’s announcement.

Will S.,

I am a big boy now. I guess I will just have to pull up my big boy britches and get on with it.

WHAAAAAAAAAAAAH!

B.B.,

Hope you fill your “extra” time with lots of fun.

Don’t forget to add an extra walk or other good physical activity for your mind and body ;^)

Printing Error

In: Piston Seal

Last sentence remove extraneous y

“Would I make a leather piston seal the(y) way I have in the past, …”

shootski

shootski,

Fixed it. Thanks,

BB

BB,

Congratulations on the new schedule. Write about things that interest you. That makes for the best blogs plus it makes it more fun for you.

David Enoch

David,

That’s my plan.

BB

There does seem to be more than a little bit of FWB 124/127 in that design.

I would love to see a review of any of the Evanix line of airguns. I also think P-Air should carry them, but then I don’t know about the business of doing that.

I will also miss the daily reports, but I then I don’t have to do the work involved in publishing them.

I will say what I told a multitude of college students. “Do a job you enjoy, someone will pay you enough to do it. Do a job that you hate, no one will pay you enough to like it.”

Mike

Custom Gen2 Tanfoglio

Finally received the Cybergun Tanfoglio Gen 2 Gold Custom Race Pistol BB replica, it is black by the way.

And it is quite a heavy handful, all metal. However, the grip is perfect with depressions for the thumb web, middle finger and pinky, making it easy to control. One of the best designs I have ever held. It may be a double stacked mag design, but the grip panels keep it thin.

The slide has a protruding knob on the R/H side to pull it back, to work better with the side mounted Picatinny rail, a flared mag well and outer barrel compensator.

The mag release protrudes a bit more than most and i accidently pushed it in changing hands. i will assume that is in keeping with the design mod for an easy quick mag change for competition.

It’s all part of the Custom-Built design. I am not saying this is a BB competition pistol, simply a copy of a real competition firearm, and an outstanding replica. Less all the fine print warning as well. What is there is dull white.

The trigger is very nice. About a 1/4″ slack take up, a dead stop and a clean sharp break and very little overtravel.

The “Outer Barrel” with compensator that drops like a 45 Colt, a little, is a bit loose, however the brass inner barrel appears to be a brass, fixed, floating type. May have some play or be in contact with the outer barrel and affect accuracy but that remains to be seen.

The slide / barrel assembly can be unpinned to slide off. The side mounted picatinny rail remains on the pistol. A true moving slide semi-auto. Ambi custom safety, no grip type. Extended beaver tail as well.

It has NO fixed sights. That replica thing. I mounted a Vism Micro Green Dot with Integrated red Laser.

This pistol seems to only be available from an Airsoft company and I assume BB does not receive samples from them, so I have gone into a bit more detail. I am totally satisfied with it so far.

I will try to check out its accuracy soon as I can. Not expecting anything outstanding. I figure being a perfect replica is its main selling point. The sight does seem a bit high for short range BB shooting

Wow, just hit the mag release again by accident. May be a good idea to keep it out of the pistol until needed.

The takedown.

Bob M,

Kool!

As far as your magazine release issue…got some of that clear snot like adhesive? Put a little on that release and the changed texture will train you not to depress it.

{I used a similar technique to train Flight Engineers(FE) and Copilots(aka Dilberts) if they had switchology problems; especially if they had “difficulties” with the fuel transfer system toggle switches.}

shootski

Shootski,

It’s not in the way when shooting and if you throw the gun up and back like a six shooter, your thumb will be resting right on it to press. It is just “Out there” and would be pressed if you simply sat the pistol on that side. The wide custom safety and flared magazine opening actually prevent that from happening.

Got the Desert Eagle 50AE as well today. Big slab of a pistol. Not sure what it’s made of,

space age plastic or mystery metal or a little of both. My fingertips just barely reach around the grip.

Not as heavy as the Tanfoglio. Still a nice-looking replica. Another day on that one

Bob M,

DANG! I saw the shadow in one of your other photographs but that is excessive!

Looking forward to your take on the Desert Eagle 50AE replica.

That firearm is on my bucket list to rent or borrow if i can ever find one to rent or borrow. Gas operated and about 40% more powerful than a typical .44 Magnum load. Apparently the gas operation eliminates some of the KICK…. Most folks that i have allowed to shoot my .44 with relatively mild loads usually don’t get through all 6 shots before they put the S&W 4″ M29 revolver down and say Thank You just not for me. I want to shoot a .50 because i am a RECOIL ADDICT :^)

shootski

Shootski,

Might look into a 454 revolver instead.

If I remember correctly my Desert Eagle had dual recoil springs riding on dual rods to reduce recoil. Combine that with the weight of it at rest and you may not have that much recoil. Best to try one out first.

A Thompson Contender in a rifle cartridge perhaps?

Just thought …that Desert Eagle 50AE I got is a BB pistol. Hope I did not mislead there. I did say Replica.

Bob M,

https://www.fieldandstream.com/guns/most-powerful-handguns-in-world

Enjoy!

S&W Model 460 shooting .460 S&W…DANG :^)

shootski

They must have had Big Foot in mind.

B.B. and READERSHIP and especially Gas Spring owners,

First for Tom: any word on you ASP20 gas spring replacement/repair?

For those of you that own a SIG ASP20 or other Gas Spring powerplant:

This is a part of my continuing study on Gas Spring powerplant Preventative Maintenance (PM) for air gunners. As understood by me that (according to one of the SIG Design Engineers one Ed Schultz postulates the piston seal can “weld” to the compression tube) I had a little time to exercise my two SIG ASP20s this afternoon. I have been trying to at least shoot each of them once a month for a minimum of 10 shots each. Thus far there has been NO loss of performance as demonstrated by the Lab RADAR. I was really pressed for time so i didn’t get a drop of RWS Chamber Oil

into them before shooting. I did however put a drop in each of the Transfer Ports and then stood them Butt DOWN/barrel UP in a vertical rifle rack.

Remember i’m the the PM guy that recommended (harps on an on about) a small bit of Silicone Oil in every PCP, Single/Multipump reservoir to keep the O-Rings and Reservoirs functional and likely corrosion free.

R.R.: Still not getting sub MOA groups routinely. The .177 was getting close today but that one has the wooden stock and is somewhat heavier. The answer IS 42.

shootski

shootski,

I would be most surprised if you achieved sub-MOA groups with them routinely. The mass helps, but you still have to fight the “nature of the beast”, even with these.

As far as the answer goes, I only come up with 36. I am not a hitchhiker though.

RR,

You are also not old enough. To get the right answer takes 10 million years. Or a couple of very smart mice.

BB

BB,

I do not anticipate living that long, most especially since they are planning to put a galactic highway through here, but I might be able to come up with a couple of smart mice.

Team

the answer is 42 , the problem is no one remembers the question.

Does anyone know if the Sig ASP 20 has been re released or if this is old stock.

a California Airsoft retailer has it listed at 447.99

SIG Sauer SSG ASP20 Break Barrel Airgun (Caliber: Wood Stock / .177 Caliber / With Whiskey3 ASP Scope)

Kind Regards

jda-001

jda001,

No indication on the SIG Site of that.

The going price for used BARE SIG ASP20s is typically way higher and even more with the WHISKEY 3 ASP scope.

There have been any number of SCAMS surrounding “new” and used ASP20s.

Tread VERY carefully.

shootski

Shootski

Thank you for the guidance. The company offering is the largest US airsoft retailer. Think they started offering airguns in the last year or two. Can we mention the name of competitors.

Kind Regards

jda001

jda001,

EVIKE.

They are reputable and that is a good price.

It looks like stock is VERY limited!

If it still works after sitting in a warehouse all this time and fits your needs and wallet you won’t be disappointed.

B.B. did refer to it as the break barrel of the millennium.

shootski

If it is New Old Stock (NOS), I would buy it at that price. I just bought a wood-stocked one without the scope for more than that at an online auction. I have seen these sell for $700 and more on ebay in used condition with no refunds or returns.

By the way, the trigger is adjustable and excellent.

RG,

I just checked by trying to load two into my cart and they still apparently have one in stock.

It is a temptation…but i have one in each caliber already and two spare ASP scopes and don’t need to get into Flipping airguns for profit.

.177 in synthetic would probably be a buy decision for me.

shootski

Mine is .22 in wood. For such a powerful rifle, I think .22 suits it perfectly. I get velocities in the 800s with a wide variety of pellets. The goal will be to testing a few lighter slugs.

I don’t mean for jda001 to buy with the intention of flipping. I only meant that if it is found not to be suitable, it can be easily resold without a loss (and if at a slight profit, so much the better). In other words, ya’ can’t lose.

Roamin Greco,

I don’t want jda011 to flip a SIG ASP20 either :^)

The .22 is fun but shooting JSB Knock Out Bullets (slugs) in my .177 is how i got the most Sub MOA groups the quickest to enter the PA contest a while back.

I have a bunch of different Mass and diameter .22 H&N boolits (slugs) to try in my SIG as soon as i get my O-2-Its in order. The absence of a Choke on the high quality SIG barrels along with the Gas Spring power profile makes them among the few Spring Powerplants able to shoot boolits (slugs) well.

I hope jda001 doesn’t miss out on a very special opportunity to own one of these great airguns.

It sounds like you are enjoying yours.

shootski

I am enjoying. I hope SIG has another sale on the Whisky Scopes soon.

In the meanwhile, I owe an airgun buddy some trigger time on the Winchester 435 (Diana 35) to compare notes….

Roamin,

I think that the Whisky 3 ASP scopes are no longer made, really nice scope and I should have got more than just one.

Mike

jda001,

Did you buy it?

Now listed as out of stock and $599.00

shootski

RidgeRunner,

36 is a Perfect number ;^)

Yes the Galaxy is a great place to thumb rides but beyond even that the number 42 is pretty amazing in how many places it shows up; to include the Holy Bible.

shootski

shootski,

Highway or not, I am staying right here.

“… I can write about firearms as well as airguns, so look for that to happen.”

BB,

That’s cool! I AM looking forward to that. 😉

Blessings to you,

dave

TDM

A good writer can describe, but a good storyteller can illuminate. We are so lucky to have someone who is both. Now that he has been given a bit more time I have no idea of what to expect. I am anxious to find out.

Ed

“A good writer can describe, but a good storyteller can illuminate. We are so lucky to have someone who is both.”

Amen! I’m with you 100% on that! 🙂