This report covers:

- What is an air transfer port?

- How transfer ports work

- Concentric versus offset ports

- Angled ports

- Summary

Today we take a look at the air transfer ports on spring-piston airguns. This is a subject were haven’t considered for some time. There is lots of talk about transfer ports on precharged pneumatics (PCP), but very little these days on springers. Today we are only talking about springers.

What is an air transfer port?

At the end of the compression chamber of a spring-piston airgun there’s a small hole that the compressed air passes through after being compressed by the piston. That’s the air transfer port. In a spring gun, the amount of compressed air is extremely small when compared to a pneumatic. As early as 1948, the gunsmith and pistol competitor Walther F. Roper surmised that it wasn’t the volume of compressed air that makes a spring gun work but the speed at which the air is compressed and released. Three decades later, the Cardews of airgun experiment fame agreed with his observation.

How transfer ports work

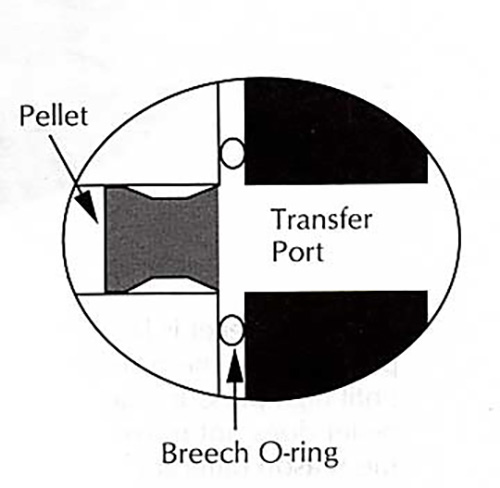

The piston rushing forward in the compression cylinder compresses air rapidly. This compressed air escapes the compression chamber and moves through the air transfer port to the breech of the barrel to push the pellet. Let’s look at an illustration.

Seen in cross-section, the pellet seals the front of the air space and the piston seals the rear (piston is to your right and not shown in this drawing). This is where the compressed air passes through to the rear of the barrel.

Concentric versus offset ports

Transfer ports start at the end of the compression chamber. Because of that they do add volume to the compression chamber, which lowers the pressure that can be reached.

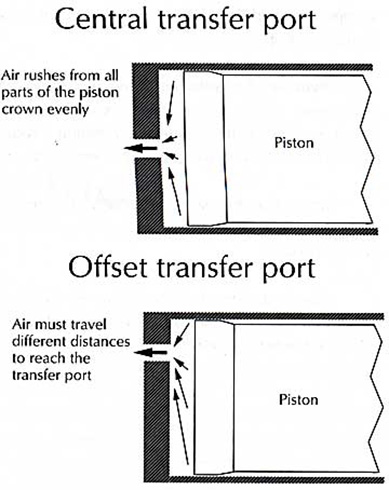

There are several different ways transfer ports can be made. If they are in the center of the compression chamber they are called centered or concentric ports. If they are closer to one side they are called offset ports. Air transfer ports are placed where they have to be to work with the gun’s design. Let’s look.

The transfer port is located where it has to be to align with the rear of the barrel.

The TX200 has a curious humpbacked appearance because the barrel is lowered to align with the center of the compression chamber. The centered port increases efficiency, giving the airgun more power. Hence, a light spring can produce greater power with less effort. The RWS Diana 48 and 54 are designed the same way and produce similar results. The majority of airguns are not designed this way, so their transfer ports either have to be offset or made longer to carry the air where it has to go.

To align the center of the barrel with the center of the compression chamber, the TX200 needs to offset the barrel like this. This makes the outside of the TX look humpbacked.

Angled ports

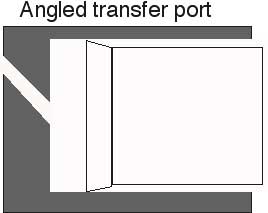

Some air transfer ports are angled so they can be centered in both the compression chamber and the breech. Those manufacturers did not want the “humpback” design of the TX200, but they did want a centered transfer port. The best way to do that is to angle the port.

The angled transfer port allows the port to be centered at the end of the compression chamber, but it increases the length and therefore the air volume of the port.

Unfortunately, when the port is cut on an angle, it has to be longer, and the extra length adds volume to the compression chamber–remember that? Extra volume means the air cannot be compressed to the same degree, and, if we are correct about the intensity of the air blast being more important than the amount of air that’s compressed, then it becomes a very big deal.

The Feinwerkbau 124/127 (and some other spring guns) have angled transfer ports. That’s one reason they can’t obtain a high velocity, while the TX200 can.

More to come

We’re not finished. We still need to discuss the size of the transfer port and also the port’s shape on both ends. This will be an interesting report series.

Tom,

This will emphasize the importance of the breech seal in preventing pressure loss especially with the angled form of transfer ports.

Siraniko

Seems to FM, who is no designer or engineer the central transfer port design is the most efficient and logical one for a springer but then if that were the only type “sproinger” built things would be boring in airgun world?

FM,

This is indeed the most efficient. I am certain that BB will further expound upon the variations of even these. You do not have to fear that things such as whether centering all transfer ports, etcetera will make things boring. “Man” will always attempt to make a better mouse trap.

B.B.

Great report! I understand that as the air is compressed, it acts more as a plasma than as air. Fluid mechanics is not my strong suit. Could AI, come up with the “perfect” TP( no not toilet paper) for each guns bore and stroke and spring rate?

-Yogi

Yogi,

AI is only as good as the moron programing it. The truth is AI is not really a new thing. It is just now being released into our world, supposedly making it better. We have seen it for some time now, giving us suggestions of phrasing or spelling. It certainly makes the jobs of teachers easier as they no longer have to instruct students in how to spell or phrase their attempts at communication.

We have also seen such where we may plug in a value, or values and AI spits out another value. We see this in such things as currency conversion, FPE calculations, etcetera.

Where it has gone astray is it is now being used to shape our very ideas and thoughts into what the AI programmers want them to be. It is also being used by some to monitor and censor such thoughts and ideas. This is where it becomes scary.

RR,

I believe you are confusing Algorithms with true Artificial Intelligence!

The difference is crawling vs Husain Bolt!

-Y

Yogi,

“Husain Bolt”? What’s that?

AI is supposedly nothing more than a program creation that “learns” as we use it. Being an old curmudgeon, I do my best to not utilize such. As far as algorithms versus what you define as true AI, that is really nothing more than the next step.

What is really scary is most supposedly intelligent folks out there who become doctors and such will utilize AI to do the research they are supposedly doing to write their dissertations to “earn” their degrees so they may look after us. Of course, the true goal of many is to make geegobs of money and they could care less about us.

What is even scarier is we will likely hand over all the thinking to these AI programs and forget how to do such. I am just glad I am as old as I am and either I will die before that happens or will see the Lord return soon.

If you have not done so, you should read “The Feeling of Power” by Isaac Asimov; FM read it as one of his reading assignments during his freshman year in high school. Even then he thought the premise of the story was scary. The author was eerily prescient.

https://meanderingminstrel.wordpress.com/2018/06/21/the-feeling-of-power-a-short-story-by-isaac-asimov/

FM,

I have read many of his writings, but not this. It is so Asimov though. He often spoke of the “Dark Side” of humanity. The sad part is though many have seen this monster, they continue to feed it.

Yogi

That is certainly true that there is a vast difference between AI and algorithms, but that difference is only in scale. AI is actually a great many algorithms “pushed together”.

That is the way computing works. Even as far back as Basic, many fairly complicated applications were written that could be described accurately as AI.

But as the applications became more and more sophisticated we started to look at them in a different way. For most they actually seemed more akin to magic than technology. Those of us that bothered to think about it realized,, as RR mentioned,, “it is now being used to shape our very ideas and thoughts into what the AI programmers want them to be”.

Those that write the codes influence the results no matter how complicated the application, simply by their own biases. OR,, by the biases of those paying them to write the code.

So, in the end,, AI is/are algorithms and are written to give intended outcomes. Welcome to the future,,, it smacks of the past, doesn’t it.

Ed

Yogi,

Doubt our present AI can come up with what you ask until somebody models the physics in a supercomputer and publishes it. AI as of now scrapes the data that man has put on the internet and makes a logical(?) word salad that may or may not be the truth. Until it has been fact checked I don’t trust AI to do anything.

Siraniko

Yogi,

The short answer is — I don’t know. But there are some more topics to come that will affect things as well.

BB,

Transfer port length is/was also a problem with airguns similar to the Gamo CFX. It had a rotating loading port between the end of the compression chamber and the barrel. This has/had a very large volume of air, greatly reducing the power produced.

The pop-up loading port of Weihrauch and Gamo fame may also be considered a large volume transfer port. So is the drum type loading port of my 1906 BSA and other similar loading ports used on the Diana 50, etcetera. The loading port of the Diana 46 is very long, even by these standards, greatly increasing the volume of the transfer port. The “standard” Webley transfer port is very unique. It goes to the rear, then up and then forward into the barrel.

I do hope I did not step on any toes with my spiel. If I did, I apologize and hope there will be further explanation and expounding on these types. I have no experience with at least one of these and would really enjoy further discussion on those, as I am sure others would also.

Just based on my experience with air conditioning air duct design, I think that reducing turbulence (smoothing the airflow) and thereby increasing efficiency, would also be a goal in spring piston airgun design. Reducing the angle of the turns that the airflow has to make, avoiding sharp corners, and use of turning vanes all help a lot in air duct design.

I am guessing these things have been used (or at least tried) before. But this doodled-on diagram helps explain some possible improvements that come to my mind. The red areas are a convex top to the piston and matching angled end to the cylinder. Yellow arrows point to corners that could be chamfered or rounded.

Elmer,

I see no yellow arrows on your diagram, but this particular design in not new. It most certainly has merit though. Unfortunately, this particular design variation will cost more than most manufacturers are willing to put into their designs. The centered transfer port, sliding compression chamber, etcetera are why Air Arms sproingers are very expensive.

Some manufacturers are aware that those of us “in the know” are willing to pay for these improvements, but the unwashed masses are unaware or unwilling to do such. There has been attempts to improve sproinger technology over the years, but profits for investors keep forcing most manufacturers to return to what is tried and true and sells now. Very few are in for the “long haul”. I have seen several very good sproinger design changes come and go because of this. This has happened with many products, not just the airgun world.

Fortunately for us, there are a few out there who do know what is really going on and are in for the “long haul”. We “in the know” need to support those particular manufacturers as much as is possible.

You may need to zoom in to see the yellow arrows (they are small and at the entrance to the transfer port from the cylinder. I agree the manufacturers that “go the extra mile” for higher quality are the ones we should support as much as we can.

Elmer,

NOW I see them!

EF: You hit the nail that I have thought about repeatedly but have no tool and die skills to effect what I’ve thought about, namely, what you brought up, the advantages of a streamlined air flow. Even champhering the bore ends would be a seeming improvement. That would be in keeping with the notion of small volume with high speed flow. Enabling that speed is important if one wants higher velocity, at least it seems so to me.

The worst air arm I have for air flow would seem to me to be the Beeman P-1/Weirauch 45 pistol. It vents from the top of the circumference of the compression chamber then does a right turn to the breech, essentially turning the air flow 360 degrees, but still manages 600 fps. Perhaps the thing that makes the severe turns still work is the extremely short transfer port pathway?

That reminds me of high compression domed pistons on a combustion engine, complete with the hemi heads. Except no need for the cutouts for the valves, but the stroke still needs to be controlled so that the piston does not impact the end / head.

Mike

Mike,

Yep. That is the way I understand it also.

Hey RR and others, I came across an interesting article explaining what AI is, how the concept was developed in the 1940’s (neural networks) and how the programmers and code writers try to steer their program to give responses in line with their beliefs, not necessarily the correct responses. It also discusses power requirements for the program(s). It’s long and you probably will have a headache by the end of the article, if you’re interested.

https://wattsupwiththat.com/2024/09/03/the-puppeteers-of-perception-how-ai-systems-are-designed-to-mislead-jonathan-cohler/

Fred formerly of the Demokratik Peeples Republik of NJ now happily in GA

Fred DORoNJ,

Thank you for that LINK.

Interesting read.

I have always refused to be a Useful IDIOT.

You and the Readership may enjoy this LINK but only after reading what BIG BLUE has to say about AI:

https://www.ibm.com/topics/artificial-intelligence

shootski

Will have to show this to Mrs. FM who was once upon a time a Big Blue busy bee.

Fred DPRoNJ,

The headache you predict is an interesting phenomenon just like having the Hangries.

ATP (Adenosine 5′-triphosphate) is the energy Bitcoin of living cells…especially our human brain. Most folks don’t have enough of the building blocks of the ATP on board to power their brains (as well as their bodies) at even half power for any significant amount of time. Without ATP, we couldn’t form a thought or move a muscle. ATP keeps our nerves firing and our heart beating. It’s our body’s “energy currency.” It’s the main energy currency not only in our cells, but in all forms of life on the planet.

I started supplementing with Creatin as an athlete for the muscle power and endurance boost but like many others i realized that at the right levels it made my brain function longer and at a higher level even more so.

AI takes huge amounts of power to build the knowledge base for it to work but the level we are currently (ab)using AI at…not much power at all. Just like most humans starve their brains of the power to function at peak mental capacity.

The buggers don’t want us thinking for ourselves at anything close to peak efficiency because it doesn’t serve their desired outcome!

Don’t be a MUSHROOM…you do know what they feed them…

shootski

I think that the collision of the piston with the end of the compression chamber is “controlled” by a defined amount of pressure build up of the air charge so that there is a cushioning effect of that air charge remaining in the air chamber. There is enough air left in the compression chamber to slow the piston before it slams into the end of the chamber.

LFranke,

You must have read that somewhere. To the best of my knowledge, this is correct. I have felt the bounce myself that will result from such. Most times the piston will bounce backward and then come forward. This can actually happen several times.

With the advent of the gas spring, this happens to a much lesser extent. This is where some have their face “slapped” with the buttstock of the air rifle. By tightly gripping the sproinger, this is felt less.

With gas springs you are also much less likely to have the air rifle attempt to rotate as with an improperly compensated metal spring. This can be accomplished in several ways, one of which is used in the FWB300 series. With this sproinger, the Germans used two springs wound in opposite directions end to end to propel the piston forward.

RR

The Cardew books cover piston bouncing off highly compressed air. Pellet weights can make a big difference on this. However I wasn’t aware of the cause of clockwise movement during the shooting cycle. My Daisy Avanti 753S groups fairly well at 10 meters but less than hoped for at 25 yards. It has a distinct clockwise movement that defies attempts to prevent it. I know it is designed for 10 meters, not longer distances.

Deck

Deck,

I have felt this issue myself when holding a sproinger very lightly. This issue has been discussed at some length in the comment section of this blog somewhere.

As you compress and release a metal spring, it will twist. FWB overcame this by using two short springs wound in opposite directions to push their pistons. Walther recently attempted to overcome this by allowing the piston to twist within the compression chamber. I personally have not taken one of these apart, but I suspect the TX200 series and the HW97 series allows the piston to turn within the compression chamber.

There is a type of flat bearing that has been discussed here that could be fitted under the end of a spring to allow that end to turn freely. I do not remember what it is called. I suspect a couple of washers with liberal amount of moly grease between them would help also.

Wow, and I thought I would manage to go all day today without learning something new. ;o)

Seriously, the angles Elmer Fudd proposes could be created by a Delrin washer that is wedged to the end of the cylinder and the other end is molded into the rubber piston seal so they match up. That does not seem complicated in a typical break-barrel springer.

Roamin Greco,

In wish you were (could be) correct!

The problem is that the air flow will even erode metal at the compression and velocities that Transfer Ports will see even without instances of DETONATION; or more (weak tea) combustion.

shootski

Shootski,

I would think that the same could be accomplished by shaping the piston seal properly (differently). I think that some of the seals are already designed to do that.

Enjoy the day.

Bill

Billj,

I would love to see the piston head and seal on my two SIG SSG ASP20s since the engineering drawings i have show an off center Transfer Port; no indication of any piston head shaping.

aside: i was taught the piston head of a fuel driven engine was shaped to provide the best fuel-air mixing by combustion chamber swirl prior to ignition as well as not impede the exhaust stroke clearance of the combustion process end products.

In the end IF the powerplant gets the job done to my satisfaction even if it is a Black Box solution to me the shooter is satisfied.

shootski