This report covers:

- Thor

- Pin punches

- Long-bladed small screwdrivers

- Magnifying glasses

- Needle-nosed pliers

- Long-bladed screwdrivers

- A good vise

- Dremel tool

- Where to find these tools

- Summary

For Americans this series will sound like one from Tim, “the Toolman” Taylor. He’s the main character in a sitcom titled, Home Improvement, that stars comedian Tim Allen.

This report series was inspired by readers Alex2no and Peter, whose recent questions about airgun repairs have inspired me to write more on the subject of airgun maintenance. Alex2no asked about the parts she needed to have to make small repairs to her spring gun collection and Peter talked about a problem he had with the valve on his GunPower Stealth, which is a 12-foot-pound UK PCP made by AirForce Airguns.

I will talk about the tools I use all the time for airgun repairs. Last week I was up to my elbows in the Haenel 312, but fortunately I had everything I needed to get the job done. That hasn’t always been the case. Back in the 1990s I fixed airguns on the kitchen table and had a minimum of good tools. But as time passed and I needed this or that I slowly added things to my tool chest.

Thor

Let’s start with my number one tool — the one I’ve had the longest and actually wore out, but will not throw away. I never had a name for him, but Alex2no had an uncle who named his small plastic mallet Thor. That’s good enough for me!

Two plastic and rubber hammers. Thor on top has been with me for 55 years. The new guy underneath has been around about two years. Is he Loki?

As their condition reflects, I use these two hammers for everything. And Peter, the black rubber part on Loki (red on Thor) is what I rap the GunPower Stealth top hat with.

Pin punches

I have owned this set of pin punches for 30 years and I recently broke the smallest one. Gotta get a new set. When I say I drift out a pin — this is what I use.

My pin punches have been through the war! I cannot do much without them.

Long-bladed small screwdrivers

Sometimes there are wee teeny screws that have to be turned. Look at the front trigger adjustment screw on the Haenel 312 trigger for an example. It is bigger than an eyeglass screw but not by much. I labored for 50 years without these screwdrivers and just recently got them. I don’t use them often, but when I need them, nothing else will do.

The front trigger adjustment screw (arrow) on the Haenel 312 is very small. Regular screwdrivers just won’t do.

These long-bladed screwdrivers are recent acquisitions, but have already proven their worth.

Magnifying glasses

I have three magnifiers that I use constantly. One is hand-held and only magnifies about 3X. But sometimes that’s all I need. I have a hood with several magnifying options and for some work it is essential. And I have a 10X jeweler’s loupe that is the recognized international standard for grading diamonds. When I’m not doing that I use it for countless other things.

I’m always using one of these magnifiers. The hood is for close jobs that require free hands. The loupe is for all sorts of itty-bitty stuff. The glass is for when my eye just can’t focus that small. These stay on my desk at all times.

Needle-nosed pliers

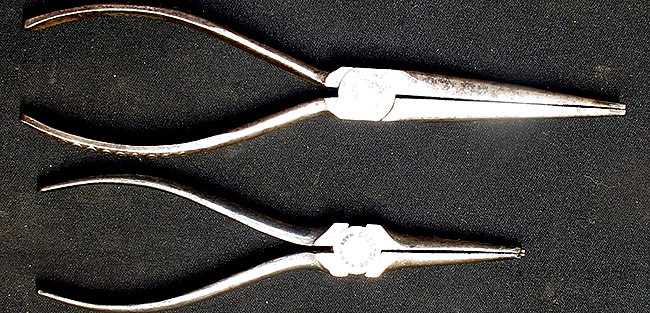

I have several of these, but two pair I almost always use. If you look closely you’ll see that someone has filed small points on the tips of the jaws of the smaller pair so circlips can be removed or installed.

My favorite two pair of needle-nosed pliers.

The tips are made to go in the small holes of a circlip.

Long-bladed screwdrivers

I can’t get enough of these. They are seldom used but when it’s time to reach into a deep hole to loosen a screw like those deep buttstock screws, this is the only thing that will work!

I look for these guys in every pawn shop I visit. I don’t need them often but when I do, I really need them.

A good vise

Not a good vice, because they don’t exist, but a good vise is essential to projects. I have several. One is small and quick to mount and gets used a lot. Then my neighbor, Denny, mounted my larger vise to a board that attaches to my workbench that he also made for me. When I need it it installs in less than a minute and when I don’t need it the workbench is bare — well, cluttered — but you know what I mean.

My red vise mounts to my workbench when I need it and is stored below when I don’t. The blue vise is quick to mount for small jobs and is the one that held the grease gun nose when I drilled it out. I included the little pin vise in the picture but I seldom use it.

I bought a set of soft jaws for the bench vise. They are slightly larger than the vise jaws, but who cares?

Dremel tool

Yeah, you gotta have one of these or you aren’t an airgunner. How else are you going to mess up so many jobs so quickly? Get a rechargeable one if you can swing it, because they allow you to work anywhere.

Get a cordless Dremel tool if you can and save all those attachments!

Where to find these tools

You can probably find everything on this list for sale online. But I have a different approach. Whenever I go to a pawn shop I browse through their used tools to see what I can possibly use. That way I’m spending ten cents on the dollar for this stuff. Believe me, it’s hard enough to find any one of these things! You’ll never break the bank if you shop this way. That’s because nobody gets rid of good tools. But their widows and kids do, so when you see something you like, make your move!

On the Dremel tool, if you buy a used kit forget the tool inside if it has a cord. It may work but who cares? Buy a used set for the attachments, only. This is a garage sale purchase for which you should only spend a couple dollars. But buy a new cordless rechargeable Dremel tool because it is so handy. And get at least one extra battery.

Summary

If you are going to be an airgunner you need a basic tool set. Today I have given you some of the basic tools I have used over the last half century. There are more and no doubt you will want to add to my list. Remember, this is just Part One, so there is more to come.

B.B.

I’m surprise you did not mention a torque wrench?

Zip ties and a dental pick is all I would add.

-Y

Yogi,

Good choices. I have several picks.

I think liquids can be considered, if not tools, then at least essential.

For example, degreasers like white spirit, alcohol or acetone.

And, of course, there are the various lubricants, like oils and greases.

In a way, at least until they’re set’n’dry, the various glues are liquid too. Oh yeah, thread-lock.

The list goes on…

Finally, some thin disposable gloves. I admit to thinking they’re just for those too lazy to wash, but now that I’ve “seen the light” they are a must for me.

Oh, and maybe a beer (non-alcoholic, of course ! [wonder what that’s like? 🙂 ]), for consolation when things go wrong, and celebration if they don’t. 🙂

Lesley Wesley, in his classic ‘Air-Guns and Air-Pistols’, gives this useful tip.

Just to clarify – is ‘the largest pipe wrench you can find’ on the list or not?

Iain

Iain,

LOL! Fortunately, I have never used it on an airgun, but I do have one capable of such!

Thanks Iain. Though downside up, I found that text interesting.

My thoughts regarding your question are, if “the largest pipe wrench you can find” should indeed make it on the list, then I would add, next to the fire extinguisher and first aid kit, a timer/stopwatch… 🙂

Ida thunk you woulda mentioned a spring compressor. A selection of different types would be extra handy.

Something I have found handy from time to time is a set of small files. I have some that are straight of various sizes and shapes and some that are curved.

Bazooka bubble gum and duct tape. And for Iain a 8 lb sledge hammer to help make the swearing stop. :o)

B.B., do you have separate punches for roll pins with the little nub on the tip? Do you ever use brass punches or roll pin punches? What is the yellow side of the hammer for? Wouldn’t a steel hammer be better for tapping the punches?

Roamin,

Yes, I have roll pin punches, but I don’t use them that often.

BB

Roamin,

The yellow side of the hammer is plastic and is what I hit the pin punches with. Sometimes when a pin is stubborn I do use a steel hammer, but not very often. I don’t have brass punches.

BB

When you introduced me to the Crosman Mark I and II, I discovered that there are several roll pins holding key parts together. So I thought the roll pin punches would preserve the pins better than a flat punch.

You know what is missing is a good set of gunsmithing screwdrivers so as not to strip out screw heads. I have a basic set and use it all the time now.

Lots of dental picks to deal with o-rings, large variety of hollow ground screwdriver tips, various milling machines and lathes. Multiple credit cards.

A good headlamp and several small, bright flashlights. You can never have too many or too much light.

B.B.,

I have many of the tools you show above. I most recently purchased a used jeweler’s vice. I should have bought one many years ago but struggled without one for two long.

I also have what is possibly the world’s largest private cache of small screwdrivers. They are absolutely necessary for air guns, but there are things I am actually good at, working on guitars, for example, that require many screwdrivers with specific characteristics that are common by themselves (a two-headed screwdriver with right-angle ends) but require that multiple special features are combined in one tool (a two-headed right-angle screwdriver that is extra small). I have an assortment of different “eyeglass screwdrivers” for different requirements. For example, I have several serious, very small long-bladed screwdrivers for some work, but I also have a couple of those cheap little eyeglass screwdrivers women are supposed to keep in their purses. They are difficult to use, so why do I have them? There are a couple of specific electric guitar adjustments that require extra small screwdrivers (usually slotted) that have especially short shafts. My jeweler’s screwdrivers have shafts that are several times too long for that. I also have an assortment of hemostats and alligator clips I use as heat sinks.

A handful of the tools I use that have become essential are a couple of different contraptions to hold work, “extra hands” devices. Guitar wiring often requires four or sometimes even five hands at a time: one to hold the soldering iron, another to feed the solder, a third to hold one component, and a fourth to hold the second component. I also must have a small fan to remove toxic fumes that are produced from soldering. I first started doing that when I adjusted, tuned, and especially cleaned the innards of very old manual typewriters. So the fan clears the solder fumes, nitrocellulose lacquer fumes and the methyl alcohol vapor (although I recently switched to Everclear).

Finally, I use a stand mounted, infinitely adjustable-arm-mounted magnifier lamp with multiple lenses which combine for different magnification strengths. I got fed up with messing with magnifiers over my eyeglasses and jeweler’s loupes. That magnifier is the single best tool I have, and the bright light means I no longer have to wear a headlamp.

An honorable mention goes to my stainless steel magnetic bowl for dropping steel parts into. The distinctive metallic SNAP! they make when the magnet grabs them is a sound I immediately appreciate any time I do work that involves small screws, washers, nuts, and anything else small and steel.

Michael

B.B., have you bought your magnetic bowl yet? :^)

And . . .

Michael,

Wowie, wow wow wow! And you can’t work on airguns? I think airguns are too large and cumbersome for you. You need to work on watches.

Yes, I have my magnetic bowl and I even have some watchmaker’s screwdrivers that you probably need. Next time.

BB

BB

We all have been had by Michael. Oh well, we had almost as much fun as Michael following the posts.

Deck

Deck,

Hah! :^) I wish that were true. I’m decent at guitar work, OK with basic guitar amplifier maintenance (especially on vacuum tube amps, not as much with solid state).

I’m terrible at, absolutely awful times two, when it comes to two things: air guns and woodworking. Granted, there are things I would probably be incompetent at working on but just haven’t had the experiences to prove it, such as electrician’s-level work. There’s a big difference between electronic and electrical. I am leery of alternating current.

So no, no con job. I assure you I am as inept at working on air guns as I have described.

Michael

B.B.,

I used to collect watches and have basic tools like a watch crab and so on, but my fingers are too thick and clumsy. Besides collecting watches gets too expensive very quickly.

Here’s one more pic, of an extra hands device for a soldering job requiring five hands (if I counted correctly).

Michael

BB, I keep this set of tools on the bench when working on airguns. That little hammer is usually all that is needed for pins. The pliers have smooth jaws. I usually have a set of gunsmithing screwdrivers on the bench as well as an electric screw driver. I find the electric screw driver is very helpful, not for speed, but it is easier to keep things aligned when using it. Like others mentioned, dental picks are often used. I have a small tackle box fun of airgun lubricants. A foam pad or a piece of carpet is nice to lay on the bench and I also use a magnetic dish to hold screws and small parts. A flashlight and other task lights are often useful.

David Enoch

B.B.

What kind of screw driver will I need to disassemble a CO2 shot valve?

Charles,

A left-handed butterfly blamaflitch! 🙂

BB

For many years, I was a manufacturing engineer involved with process and assembly of electronic components, circuit boards, and higher level modules and appliances. When I worked for Fujitsu, my Japanese manager had boxes of screwdrivers, common #1 and #2 Phillips type, which he called “cross” drivers. He had them shipped from Japan, they were Vessel brand. His belief was that there was a difference between the American and Japanese standards. There was a noticeable improvement using these Vessel brand tools. You could hold the screwdriver straight up, put a screw on the tip, and roll your wrist to have the driver in horizontal position, with the screw holding in place (not by magnetism).. I tried to find drivers locally that could do this, and had little success. I even gave a Vessel screwdriver to a sales rep for Xcelite. In a few weeks, I received a polite and very specific letter with a diagram showing the grind angles and relief of a Phillips patent driver bit. He admitted that the tooling used at their factory was worn and did not meet certain limits.He thanked me for making this obvious to their staff. My Japanese boss was much amused. I notice that your small screwdrivers are Wiha brand, and I have tried my simple test on their bits, finding them pretty good. Still, I have several Vessel brand (not usually available in the USA) and they work so much better than most, – I do suggest that these basic #1,2,3 sized drivers made by “brand” manufacturers can cam out and damage a screw that will come right out with a good driver bit.

This guy on YouTube does amazing tests on tools, and this video on screwdrivers does test “camout” and even has the Vessel brand under test. https://www.youtube.com/watch?v=xtZ2jh_J7XE

Maybe you should import these wonderful little Japanese screw drivers.

My welding buddy calls the screw drivers, “plus” and “minus”.

-Y

About twenty years back, I wrote to Vessel, and inquired about becoming a US distributor. They said they were not interested. I see that they are now being sold here. The comments on the Amazon review page all say they like the screwdriver, but allude to “JIS” (Japan Industrial Standard) screws. I am almost certain this is a fallacy. I had sent a copy of the FN (Fujitsu) standard drawing for the screwdriver bit, to Xcelite (Cooper Tools), and they returned a copy of the original WW2 era Phillips patent drawing. It was the SAME, except for the language. We used those Vessel drivers and bits on US sourced hardware, and they were very noticeably better. The screw relief and driver machining are very precise. Of course, we usually have no control on the screws, and they are a factor. But my main point here is to look for quality in a Phillips type driver, examine for wear, as the difference between the “bite” of an unworn bit in the screw recess is very significant. Even quality driver bits in power tools must be replaced regularly, or wear will have major adverse effect.

https://www.amazon.com/Vessel-Megadora-900-Screwdriver-Original/dp/B000TG8OTY/ref=asc_df_B000TG8OTY/?tag=hyprod-20&linkCode=df0&hvadid=309869401414&hvpos=&hvnetw=g&hvrand=14083622776686035618&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9033815&hvtargid=pla-421878978938&psc=1&tag=&ref=&adgrpid=63364097444&hvpone=&hvptwo=&hvadid=309869401414&hvpos=&hvnetw=g&hvrand=14083622776686035618&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9033815&hvtargid=pla-421878978938

Yogi, I see there are Vessel tools online now. I still treasure my #1 and #2 Vessel screwdrivers, one of the Japanese engineers I worked with brought them back from Japan in his suitcase and gave them to me, back about 1990. They are tang-through, with wood grips. They feel great and work beautifully. Strongly magnetized. I see that the same model are actually available via Japanese eBay sellers. They are like an Estwing hammer or a Randall knife IMHO.

BB I think you need to purchase a set of these Vessel screw drivers. So I can borrow them. 🙂

sawdust,

This is my neighbor Denny, folks.

Maybe BB will buy a set for Denny in thanks for all he has done for me! 😉

BB

I’m glad someone finally mentioned JIS screwdrivers (Japanese Industry Standard). Early on, working on early Japanese motorcycles with their side cases held on with cross head (Phillips screws) screws would result in several stripped screw heads necessitating the use of a Harley wrench (hammer) and screwdriver (cold point chisel). It seems that Phillips head screwdrivers were designed early-on to allow the drivers to “cam” out of the screw head so as not to over-tighten them. The JIS drivers don’t have this feature and I’ve found them to be very useful for any screw, Japanese or American standard. Just do a search for JIS screw drivers – not expensive and you can even get bits for fitting into power drivers.

Fred formerly of the Peeples Demokratik Republik of NJ now happily in GA

BB,

Instead of Loki, I think you should name your second hammer Mjǫllnir, which is what Thor’s hammer was called in Old Norse (Mjölnir in modern Icelandic).

The word for a bolt of lightning in Russian and some other Slavic tongues is derived from Mjǫllnir by the way.

Talking of bolts from the blue, there was some alarming news on the front page of Morgunblaðið this morning; the creeping bureaucratic dictatorship known as the European Union is banning the use of lead shot in all EU and EFTA countries from 15th Feb 2023! The pretext for the ban is the protection of European wetlands.

I am worried that the Brussels commissars will ban lead airgun pellets next. Time to start stockpiling methinks.

Bob,

If I coulda figured out how to type those fancy characters on my computer that’s exactly what I would have done. I even looked it up, but there is no spelling I could find that uses English characters.

BB

I only recently figured that out-if you google “alt codes for special characters” you’ll find charts with the codes and symbols-you just hold down the alt key; and type in three or four numbers-presto!

Coolest thing I’ve even seen : )

Jesse

Jesse,

Praise the Lord! BB can now do it too! 🙂

BB

No measuring tools? A 6″dial caliper is one of the handiest measuring tools there is; next to the tape measure and 6″ rule… A Sharpie marker too…

I see the BFH for when all else fails has already been mentioned; LOL…

Allen keys? Hex bits are nice; but short-Allen keys let you reach in there if necessary; though I haven’t seen SHCS used on airguns all that often.

Ironically; the tool that I have used the most often on my Diana 350 N-Tec is my Leatherman-making sure the stock screws are tight in the field… Also a small hex key for the scope mounts too.

Jesse

Lots of good information and tips here. Best thing FM did lately was purchase a gunsmith’s screw and nut driver set; saw it sitting looking lonely on a shelf in the Big Box sporting-goods store. It has come in handy already for the care and maintenance of Casa FM’s residents.

Now if someone qualified publishes that airgun maintenance-and-repair-for-idiots book, FM will buy a copy. 🙂

I use a very bright 50 watt LED lamp over the workbench, and all of my small hand tools I keep in a harbor freight wood machinist tool chest.

And a good rubber work surface that has raised spikes to keep the screws and small parts from rolling off the work bench.

The ones I use the most?

The gunsmith screwdriver set.

Dental picks to remove orings,

Specially tools I have modified to work on the co2 caps of the Crosman Mk1&2 guns.

Small brass hammer and punches.

Small Allen keys in both metric and SAE.

Ian

The tool chest

The work surface and a new to me MKII

45Bravo, that MK II makes for a pretty picture! –Michael

Thank you.

After cleaning the barrel it shoots good as well as shown by the center 5 shot group.

It was sold on gunbroker as not working.

It just needed a little pelgun oil.

It already has urethane seals in it. So someone in its past has resealed it.

Ian.

“My pin punches have been through the war! I cannot do much without them.”

B.B., ditto that! Great report; thank you. 🙂

I am a Millwright , used to work for Shell, we where bought out by Pemex, so now I work for Mexico, ya. I have a co-worker who’s numero uno tool is a hammer so we call him martillo or Mateo. He messes up more than he fixes with the hammer. . i have more hammers than I can remember but they range from 6 oz to 4 .lbs and all have a specific job. I submit, Mateo.

Perhaps it is too common place in our present time, to think of it as a tool, but our camera on our phone can be a real “angst preventative”. I have used mine for any number of “easy” projects that proved to not so easy.

Also, a “lead sled” can be useful for things other than sighting in. I use a set of gun mounts for ATVs mounted to a 2×4. I clamp it to my table (Judi won’t let me drill any holes)

I am expecting I will invest in a few of the suggestions, here. Most of my tools tend to large and blunt, due to my previous occupation.

Ed