by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Important discovery!

- Analysis

- Setup

- JSB Exact

- Evaluation

- Test restructure

- Predator Polymag

- H&N Field Target Trophy

- H&N Baracuda

- Crosman Premier

- Benjamin Cylindrical

- Velocity comparison

- Retest of JSB Exacts

- Cocking effort

- Discussion

- Going forward

- Testing new designs

Today I will test the Vortek Center-Latching Air Piston in the Beeman R9, with the pressure set at 50 bar, which is 725.19 psi. This is the highest pressure to which I have set the unit, so today’s velocities should be the fastest we will see.

Important discovery!

Before we begin today’s test, a remark made by reader GunFun1 to the last report triggered some unplanned testing that revealed some surprising results. He was concerned by my remark that some spring-piston guns (and that is EXACTLY what this center latching unit is) need a “wake up” shot when they are first fired. I have seen this with perhaps half of the springers I have tested over the years. Here is what he asked me.

“BB , Maybe next time you shoot the gun after it has set all that time. Do about 4 or 5 shots over the chrony and see if velocity is low on the first shot.

I’m guessing it will be ok but something to look for.”

So, the day after the last test (which was the day he posted that comment) I chronographed the rifle again with Crosman Premier pellets. I got different numbers, so I chronographed the rifle again a week later and the results were even different from those. Let me show you.

Crosman Premier .20 caliber pellets

Average in Part 3……..One day later……..One week later

528 f.p.s……..………….508 f.p.s……………419 f.p.s.

Cocking effort

27 lbs………………….didn’t record…………..21 lbs

Analysis

I didn’t answer GunFun’s question with this impromptu test, but I did uncover an issue. You may recall that in Part 3 I pressurized the CLU to 500 psi. That was far below the minimum recommended by Vortek, and I knew it. They really didn’t give me a lower limit, though we did discuss 600 psi as being very low. I was testing the limits of the unit by what I did. I wanted to know how light I could make the cocking effort, to see how tame the R9 could become. Well, it looks like I went too far.

I went so low in pressure that the CLU leaked air slowly. The internal pressure apparently wasn’t enough to shut the valve all the way. It didn’t affect that first day’s testing, but it wasn’t going to hold pressure where it was. At least that is what I think happened. At any rate, I need to conduct another low-pressure test. This time I will go to 600 psi and we’ll see if that will hold. I will also do the test GunFun1 asked for, but I’ll report on it next time. I will explain what I mean in detail at the end of this report.

Setup

I disassembled the R9, removed the unit, repressurized it to 50 bar (725 psi) and assembled the rifle again. All of this took me 30 minutes.

Now, let’s see what this pressure gives us.

JSB Exact

Shooting JSB Exacts the rifle started out with three powerful detonations. The velocities were 847, 778 and 913 f.p.s. Shot 4 was not a detonation and registered 699 f.p.s. Shot 5 registered 659 f.p.s. and was the start of the 10-shot string that I recorded. The average for that string was 650 f.p.s., and the spread ranged from 643 to 659 f.p.s. Lest you think I started recording too soon, shot number 8 in this string was 658 f.p.s. As it turns out, though, I think I did start too soon and I will address that in a bit.

Evaluation

In the first velocity test (found in Part 2) this pellet averaged 689 f.p.s. with a 21 f.p.s. spread. The spread this time was 16 f.p.s. At this point in the testing I was stumped, however, at the end of the report I will discuss everything in detail.

It is possible that the CLU requires a break-in period. We are also assuming that the gauge on my hand pump is exact and repeatable. But it might not be — especially at this very low air pressure (725 psi is on the low end of a gauge designed to read to more than 4,500 psi).

Test restructure

I think a restructure of the test is in order. What GunFun1 suggested now makes more sense than what I have been doing. For the next report I will first rerun a small portion of this test with the rifle exactly as it is today. I won’t do anything to it.

I will also shoot another string of JSB pellets at the end of today’s test, to see if the velocity has changed over the course of the few shots in the test. For now, however, today’s test will continue as planned.

Predator Polymag

Predator Polymag hollowpoints averaged 632 f.p.s. with a 27 f.p.s. spread (614 to 641 f.p.s.) In the first test they averaged 672 f.p.s. with a 16 f.p.s. spread (662 to 678 f.p.s.).

H&N Field Target Trophy

H&N Field Target Trophy pellets averaged 721 f.p.s. with an 8 f.p.s. spread (718 to 726 f.p.s.). In the first test they averaged 763 f.p.s. with a 9 f.p.s. spread (758 to 767 f.p.s.).

H&N Baracuda

The H&N Baracuda pellet averaged 641 f.p.s. with an 11 f.p.s. spread (637 to 648 f.p.s.). In the first test they averaged 676 f.p.s with a 9 f.p.s. spread (669 to 678 f.p.s.).

Crosman Premier

The obsolete .20 caliber Crosman Premier pellet averaged 627 f.p.s. with a 14 f.p.s. spread (618 to 632 f.p.s.). In the first test they averaged 662 f.p.s, with a 15 f.p.s. spread (654 to 669 f.p.s.).

Benjamin Cylindricals

The Benjamin Cylindrical pellet fits the R9 breech very loose. Most of them fall into the breech by one-eighth inch, or so. In this test they averaged 605 f.p.s. with a 42 f.p.s. spread (576 to 618 f.p.s.). In the first test they averaged 642 f.p.s. with a 46 f.p.s. spread (620 to 666 f.p.s.).

Velocity comparison

Here are today’s velocities compared to the first test’s velocities.

Pellet…….……Today………First test

JSB……………..650…………689

Predator………..632…………672

FTT………….….721…………763

Baracuda……….641…………676

Premier…………627…………662

Benjamin……….605…………642

Retest of JSB Exacts

At this point, I retested the JSB Exacts. This time 10 shots gave an average of 639 f.p.s. with a 16 f.p.s. spread (631 to 647 f.p.s.) I think 639 is enough slower than the first time (650) that something is happening. I would like to believe the CLU is settling down after being adjusted, but I will address that in the discussion that follows.

Cocking effort

I noticed as I shot the gun today that it was cocking much easier than I expected. On the bathroom scale the R9 now cocks with 30 lbs. of effort. You will remember that in the first test, when (I thought) the CLU was pressurized to 675 psi, the rifle cocked with 36 lbs. of effort.

Discussion

Obviously this test is not developing as expected. If the pressure in the CLU is higher, shouldn’t the velocity also be faster? Several things could be happening.

1. The CLU I am testing could have developed a leak.

2. My hand pump gauge could be reading wrong.

3. I might have read the gauge wrong for the first test — which now seems very likely.

4 What Ben Taylor once warned me about has happened. I have exceeded the operating pressure range of the CLU and the velocity is dropping. If the cocking effort was higher today than in the first test I could believe that, but it’s lower, so I think this is not very likely.

Going forward

Here’s what I plan to do. I will retest the rifle in one week without doing anything to the rifle. I only need to test a single pellet of the 6 that are in this test, plus I need to retest the cocking effort. If one pellet is significantly slower, they all will be. I plan to retest the rifle with JSB pellets, since I tested them twice today. I will use the second average velocity of 639 f.p.s. as the baseline. That assumes the CLU does need a break-in period. If the retest comes out within a few f.p.s. of 639 with this pellet, I will say we can rule out any leakage. That being said, I still think the last test at 500 psi was too low for the unit.

Once I’ve done this, I will know what the next step should be.

Testing new designs

The CLU is a brand new product and I am no doubt testing it in some ways that Vortek never did. You are watching me test the unit step-by-step. Some folks understand this, once it is explained, but some don’t. They feel that, if something is in writing it should be the final result, and everything should have been done before the blog was published. If I worked that way I might be able to publish one blog a week. The rest of the time I would be testing.

My way of writing allows you to watch behind the curtain, and sometimes you will see stuff that the rest of the world never sees. Don’t form any opinions about the CLU — yet. Let me conduct the next test and we will see where that takes us.

B.B.

Now you have to leave it for a week to see if it continues to leak and what the first few shots will be.

I can hardly wait.

-Y

B.B.,

So much for a pneumatic piston that can be adjusted to one’s delight. I’m not disappointed, it would be too much to expect that this gas piston would have such a wide operating range. Vortek would probably end up making two types of this CLU piston, one for the 12fpe market and another for the high powered market, if they decide to market this. This is where testing by an outside party helps the developer because the one testing will subject the product to conditions that the developer did not imagine.

Siraniko

PS: Section Benjamin Cylindricals

First sentence: The Benjamin Cylindrical pellet fdits (fits) the R9 breech very loose.

Siraniko,

“There you go with the negative vibes”. Theoben used to have adjustable gas springs. I do not know if they still are, but the Hatsan Vortex gas springs used to be adjustable. Keep in mind this is a prototype. We are witnessing part of the research and development of a new product. This thing does not even have an official name yet. There are bound to be issues. This is why you do this kind of testing. I hope I am wrong, but from what I am hearing here and there, the Diana / Snow Peak venture may not work out too well.

RR

I don’t think there are no issues with the AR ram BB is testing.

I think he is just showing the nature of the best I guess I’ll call it. I think he’s just telling us basically how air works in this particular case of how it’s used to make power.

Look at how air and temperature affects a pcp. Or even a multi-pump.

I personally don’t see the air ram having a leak down problem. I see more like the air is warm when the ram is filled due to high pressure flow. Then cooling and stabilizing as time goes.

That’s the difference between a nitro piston. Or should I say nitrogen piston. And a air ram. They got different working personalities if you know what I mean.

All in all I would be more than happy with one of the gas Rams BB is testing.

GF1,

So you think the AR ram has issues, eh? 😉

RR

I know I saw my miss spell.

And nope no issues. 🙂

Siraniko,

I forgot to mention that if they should market for the sub 12 FPE market, it will have to be nonadjustable so that the owners cannot adjust the power up.

RR

Yep true. And even so that would be fine with me.

I just hope it comes available soon in some form or another.

RidgeRunner,

Woof! Woof!

Siraniko

LOL!

RidgeRunner,

Actually they should still allow adjustment but not allow it to go above a certain pressure. Most of the shooters there have found accuracy in the power range between 10 and under 12 fpe. Moriarty always did make the “Negative Waves”. 😉

Siraniko,

I wonder how many others remember that?

RidgeRunner,

We’ll find out when anybody reacts.

Siraniko

Siraniko,

Fixed it. Thanks.

B.B.

BB

The extra air in the CLU that leads to a heavier cocking pressure and not really much of a gain in fps reminds me of those magnum springers that have like 4 inches of extra spring preload that isn’t needed at all.

So basically once you get in that right range of working air. That’s what the CLU will deliver. You could go higher or lower with fill pressure but your really not gaining or loosing much to a point. It seems that it’s more beneficial to lean towards a mid range fill pressure and towards the low fill. But the higher fill doesn’t really do much at all but give you and the gun a work out.

And I still am a big fan of this air ram. I really do want one. In the right gun of course. And that makes me wonder what kind of shooting exsperiance would come out of a 54 Air King. I think that would be a cool combination with it’s recoil system and a smooth cocking gun.

Matter of fact does it? Or did you mention if it smooths out the cocking stroke with the CLU?

And I can’t wait to see the results when you shoot the next time. And lots of interesting data today. Cool stuff.

G’day BB

Looks like we are talking 30-50 fps spread.

Another variable may be the light intensity with the chronographer. Maybe try two chronys or that MagnetoSpeed?

Cheers Bob

But the thing is we need to see some shooting results on paper. That will tell if the fps spread really means anything.

BB,

This is cool. Not only are we getting a glimpse behind the curtain, we are looking over the wizard’s shoulder.

I would indeed like to see a good adjustability range from this. It would be so nice to be able to “easily” tune a sproinger to the optimum performance level and also to various levels as one desires.

I will be looking forward to the next installment.

RR

I think it really can.

I think a good gauge that reads finer increments is what is really needed. That way you can hit that magic pressure your after.

B.B.

This is great stuff!! Looking forward to more of the same!

I like the way you are testing the extremes to determine where the “window” of practical adjustment lies.

I vividly remember how my father taught me to tap a thread. He gave me a piece of steel, a tap and the box of drills, his only instructions were: “break the tap”. I drilled a series of holes from “too big” to “too small” and proceeded to thread them until the tap jammed and snapped. Learned a lot from that – you can really feel what the tool is doing if you pay close attention. I have been applying this principle all my life and it has served me well.

Thanks for the peek behind the curtain – its greatly appreciated! 🙂

Hank

Great testing B.B. can’t wait for the results,I wonder if the piston was filled with nitrogen the results would be different?

Iceman,

Welcome to the blog.

Nitrogen would be better because it is dry, but not many airgunners have access to the equipment to fill with it. Yes, I know an industrial gas supplier is where you go but it’s the adaptors that are the problem. Vortek has reduced the filling to as simple a task as it can be.

B.B.

I also was wondering about a nitrogen fill as it is more consistent over temperature variations. I understand that this unit is not made to be tested that way. Stick with air only for this series of tests. Thank you.

Gerald

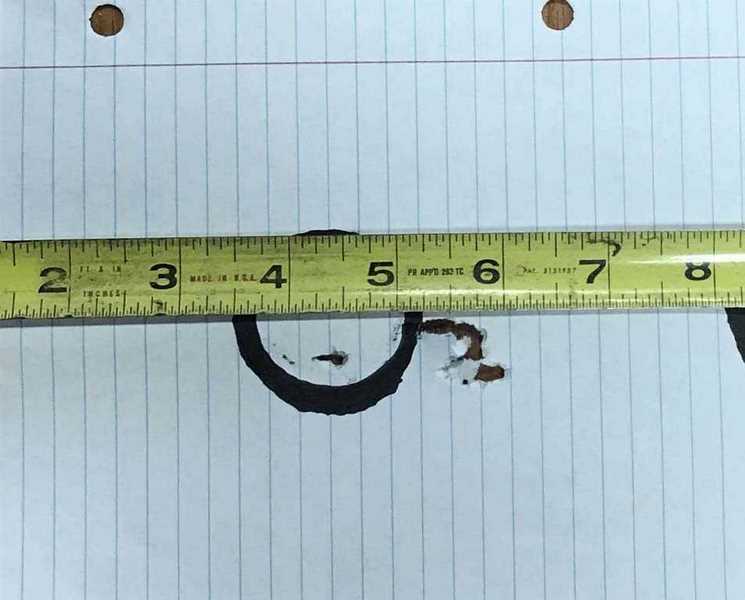

Ok now we are getting somewhere. This is after a wire brush cleaning and I took a small half round diamond file to the muzzle. After cleaning and looking from the breech I could see a small burr between 6:00 and 8:00. I very lightly cleaned it up and much improved. The shot to the left was my first shot.

Carl,

Isn’t this fun? You are getting sucked into the deeper world of airgunning!

B.B.

B.B.

Is frunstrating a word because it kinda sums it up?

I have learned so much with this little project and got an eighty year old gun flinging pellets in the process so win -win here!

Carl,

Which one is this?

What is the range?

Inquiring minds want to know.

Carl,

By the way, you have my permission to invent words if you so desire.

Now I’m on to screw head repair 101.

R.R.

Sorry it’s my em-ge 10 yds with a front rest on the back of a chair. I just took a shot through the crony 559 FPS with Crosman Premiers that’s exactly what it’s supposed to shoot at. It’s super smooth at least to me so I’m surprised it’s not shooting better,I’m using readers with sharp sights and a blurry target.

Carl

B.B.,

My FWB 300s and 150 need to wake up each time I shoot them. The first shot is usually about 600 fps., and after six or so shots, especially if I take them at a pretty quick pace, they get up over 650 fps. and the variations shrink as well. I suppose the gliding system adds to the factor as it, too, needs to warm up a bit.

Michael

BB,

When I’m trying to find the sweet spot in the power curve of a new gun I use my “Lighted Magnifier” app on my cell phone to take a frozen image of my gun’s tiny gauge and then I can really scrutinize it to determine what the pressure reading is, more exactly than I could just by glancing at the minuscule dial face. Of course that doesn’t make an inaccurate gauge accurate, but if the issue is having trouble judging between graduations on the dial face, it really helps.

Maybe Vortek would be willing to send you a fixture to fit between fill port and pump that was equipped with a gauge of a more appropriate range. After all, you do seem to be doing some of the frontline testing for them, whether that was their intent or not.

Half

Half,

The app idea is not bad. I will try it.

B.B.

B.B.,

I was going to comment this AM,… but could not get a question fully thought out with minimal time. Some 13 hrs. later,… I think I have formulated it.

Did Vortek give you full details of their testing and all parameter’s tried,… or,… did they just give you some basics and let you have a full go at it?

Chris

Chris,

Basics and go at it, Just like anybody who buys the same product.

B.B.

The cocking efforts over the 3 tests and the 3rd sub test seems to indicate a possible overfill,but the unit could be bedding in too. The spreads are consistant, with the exception on the 1st test. Seems very pressure/temperature

sensitive.Precision filling required. Also, the issue of seals rears its ugly head. Maybe a well tuned springer is still the gold standard for reliability and nearly as smooth? relatively simple to change out a spring. Still no two stage cocking rifle springer on the market, but I hope this dashpot unit has more secrets to reveal. Also, perhaps this units needs different cocking lever geometry

than a spring gun? Thanks for the view from the inside of testing! very Kewell. Best, R