by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Update on the 2017 Texas Airgun Show

- Update on the V-300

- The test

- Crosman Copperhead BBs on high power

- Air Venturi Steel BBs on high power

- Air Venturi Steel BBs on low power

- Crosman Copperhead BBs on low power

- Summary

Update on the 2017 Texas Airgun Show

If you have plans to get a table at the 2017 Texas Airgun Show, you had better move fast! The inside of the hall is almost sold out! AirForce and Sun Optics have decided to move outside, to make more room inside for private dealers, but there is still not much room left. There will be room on the covered porch outside the hall, and there will be two large swamp-cooling fans to help with the heat so there is still some room left, but when that is filled the show will be sold out.

I expect to announce a major attraction soon who will draw many more firearms shooters. He is coming to film the show for his You Tube channel. Those who attended last year will tell you this show is jam-packed and there is a lot of money spent, so make your reservations today. For registration information, read their show flier. Now, let’s get to the report.

Today we look at the accuracy potential of the Crosman V-300 BB pistol. Before we begin I want to remind you that this pistol was made in 1963-64, a time when BB guns were not expected to be accurate.

Update on the V-300

A reader found and read the V-300 manual on the Crosman website and discovered that the pistol has only two official power levels. Two clicks back on the cocking lever is for low power and three clicks is for high. The first click is just for safety and is not intended for shooting. That corresponds with my findings in Part 2. I had no intension of shooting the pistol on one click today.

The test

I shot the pistol from a rest at 5 meters. I was seated and the hand that held the gun was rested on a UTG Monopod. I shot 10 shots at each target and used a 6 o’clock hold on the bull.

Crosman Copperhead BBs on high power

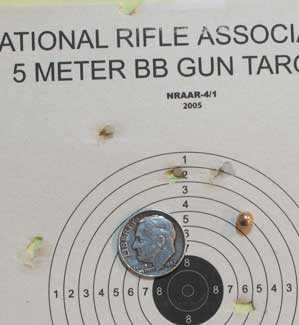

First up were Crosman Copperhead BBs. I shot them on high power, which is three clicks back on the cocking lever. The BBs don’t cut a sharp hole, which makes it difficult sometimes to know whether a hole has one or two shots in it. As close as I can tell, 6 Copperhead BBs hit the target paper. It might have been 7, because the hole on the left looks larger than the others, but it’s not that clear.

Either 3 or 4 BBs missed the target paper altogether from 16 feet! What we see is a 3+ inch group. Who knows what we don’t see?

Either 6 or 7 Crosman Copperhead BBs hit this target on high power at 5 meters. The hole on the left may have 2 BBs in it. And there is a nick at the top of the paper that is a BB hole. These shots are about 3.25-inches apart.

Not an auspicious start! I wondered if this was due to the pistol or the BB. The next target would tell.

Air Venturi Steel BBs on high power

Next to be tried were Air Venturi Steel BBs. I shot them on high power, also. This time 9 BBs hit the target paper. These shots are about 3.5-inches apart, but there is that 10th shot that’s nowhere to be seen. Another inauspicious result.

Nine Air Venturi Steel BBs hit this target paper. One has nicked the top again. These are about 3.5-inches apart at 5 meters.

This was hardly better. I wondered whether shooting on low power would help the situation, so that’s what I tried next.

Air Venturi Steel BBs on low power

This time the BBs struck the target paper lower by a couple inches. And this time I think all 10 BBs hit the paper. Two of them must have gone through one hole, but they are clustered close enough together that I think I didn’t miss the paper with a shot. This group is right at 3 inches between centers.

I think there are 10 Air Venturi Steel BBs in this group. It’s right at 3-inches for 5 meters.

There was a marked difference in the low-powered shots. The discharge was quieter and the sound of the BB hitting the target and cardboard backer was louder. The reason for that will be apparent on the next target.

Crosman Copperhead BBs on low power

On low power Crosman Copperhead BBs didn’t penetrate the cardboard backer all the time. Then just embedded in the cardboard with a solid “thwack!” When I went to retrieve the target I could see 3 BBs had not gone through, so, instead of just the target, I photographed the entire backer with the target still taped to it.

I think all 10 BBs hit the target this time, as well. If that’s true, the group measures about 3 inches between centers.

Maybe 10 Crosman BBs hit the target at 5 meters on low power. Three are still embedded in the backer board on the bottom. The shots measure about 3-inches between centers.

Summary

The Crosman V-300 air pistol was an interesting airgun to test. Not much has ever been written about this strange beast, so this report now constitutes a large part of the body of knowledge .

As BB pistols go, this one is certainly not that accurate. And the power of the test gun is below the rated velocity. Still, this is a BB pistol that few people ever get to see, so please enjoy these three reports.

B.B.

With a cool name like Crossman V-300 BB, you would expect more.

-Y

BB what are lead free pellets made of (the accurate ones)? And are they meant for shooting in lower powered rifles only ?

Riki,

I don’t know for sure, and the pellet makers aren’t forthcoming with information, but bismuth is one metal that is popular for such applications. These pellets will work in higher-powered airguns, but in high-powered spring guns they let the mechanism beat itself up a little, so I don’t advise it.

B.B.

I thought for a moment that I was Bill Murray in Ground Hog Day,.. seeing the same picture again 4 days later. 😉

Yes, your historical reports do provide an additional knowledge base/record on something that may be little known about or forgotten.

For other bb shooters, try putting some duct tape on the back of the target paper or play around with other types of tape. You should see some improvement in the holes. bb’s are tuff no matter what.

Good Day all,…. Chris

So we’re not likely going to see this pistol at the Olympics huh? I had such high hopes for it. Maybe if it had not been so tired it may have done better, but it seemed to be grouping better on low power.

With this kind of performance and the frequent breakage of the cocking lever, one can understand why there is not much out there on this pistol. We thank you for another notation in the history books.

B.B.,

That’s kind of sad to see that low level of accuracy from such a cool-looking gun.

Great report, though! Keep up the good work. =D

take care & God bless,

dave

Hi I am new to collecting. I can get a old Crosman 2100 for $100. Is it better to buy a new one at $70. Did the quality of the product change over time? In general is it better to buy older rifles? Thanks for this site it is the best site in the world for air rifle info.

Oester,

Welcome to the blog.

In many cases it would be better to get the older rifle, but I think the 2100 is an exception. I don’t believe they have changed too much over the years. Does the old one have a wood stock? Even if it does, I think a new oner is the best way to go.

B.B.

Hi Sir let me state firstly that I have the greatest respect for you as a person and that I value your opinion on the subject of air rifles above anyone else. Yes the old one has a wooden stock. The problem with South Africa is that the retailers import ad hoc what they think will sell. So I will have to get a new one from the USA. I try to purchase 2 rifles a month for my collection. I also have the option on a Gecado 27 and 35 (Diana) now. Maybe if I can save up enough I must just order what you recommend to be purchased new in one order (at Christmas !!) and so reduce the shipping costs. THANK you for the prompt answer.

Oester,

GET THE DIANA 27!!! That’s the one you want. Don’t get the 35. They are too harsh and not that much more powerful than the 27.

Then, read this report and try to do what I did to tune your rifle:

/blog/2009/05/diana-27-part-10/

I know the Crosman 2100 sounds exotic to you because it’s foreign, and the Gecado 27 is probably a lot like many of the airguns you already have. But the 27 is the best air rifle in the world. That ball-bearing trigger can be adjusted to a razor’s edge. So, unless hunting is your chief concern, get the 27.

B.B.

Hi Sir thank you very much I might even get two then – my wife also shoots. I do not mind having many rilfles that are almost the same. I can also get a old 27 with just the wooden stock without the piece underneath. (Looks like a long pistol). If you say so I will get that as well. Thank you so much may you have a long and healthy life still to guide your students.

Oester,

That one isn’t the 27 I was talking about. The 27 I’m referring to has a full stock.

If you ever order from the States, get a copy of the latest Blue Book of Airguns. It helps identify many of the older rifles.

B.B.

HI Sir I can also get a Gecado Mod 50 which I believe is a Diana 50. Only one problem niggles me the photos I have been sent by the seller has a square steel ‘thing’ in front of the trigger guard. Looks like a small magazine but cannot be. The pellet loads via a tap at the top. So what is this and is it a genuine Gecado 50 then? I have not been able to find a review done by you on the Diana 50 is this correct? Have a great day sir. My Mod 27 is on it’s way it is pristine like on the day it was manufactured the steel gleaming and without a single scratch. Thank you so much for your time.

Oester,

There is nothing inn the front of a Diana 50 triggerguard that I am aware of. I own a Diana 50 and the triggerguard has nothing in front of it.

There are Indian, Japanese and South African copies of BSA rifle. Maybe there is a copy of a Diana 50?

B.B.

Hi Sir I have a photo if somehow I could upload it you could see for yourself. It says Gecado Mod 50. I am sure it is a copy of a Diana 50. They want $195 for it. Is it a fair price? Thank you so much…

Oester,

No way to upload photos here. Email me at blogger@pyramydair.com and I’ll contact you directly.

B.B.

Hi Sir I have done so. Thank you so much. You are one of a kind.

Hi Sir OK I get what you are telling me. All I was trying to say I can get both the full stock one and the “pistol” type one. So on your advice I will get the full stock one. Thank you for your time and advice I really appreciate it

B.B.,

Had to smile as I read your V-300 accuracy report. It reminded me of the trials and tribulations I went through after my Marksman 1010 pistol stopped working. I took it apart, cleaned and lubricated everything that moved, and got it working again. Started shooting it and thought I had broken something, as I wasn’t able to reliably hit a soda can at ten feet with it. I guess you would call it minute-of-garbage-can accuracy.

I felt really bad until I found your old 1010 review and read that your results were about the same as mine. Made me feel a whole lot better (!)

Dave

Dave,

A Marksman 1010 will hit a garbage can as long as it’s muzzle is inside the can and pointed at the can’s bottom. 😉

B.B.

HAH! Love it.

Dave

On that note.

Here’s a blog for you to do. Why were some guns ever made?

Nowing you. You already done a blog on that. 🙂

Ok I got to post this.

I was just shooting my hopped up FWB 300. I was loading one of the JSB 10.34’s as normal. I felt the head drag on the rifling as usual as I was loading.

But check this out. Rifling twists. Right? Well to the best I can tell the pellet did not twist. I use the bottom of my thumb to seat the pellet skirt flush in the barrel when I load. I tryed several times even with a bright light and slowly pushing the pellet into place and watched and tryed to feel on my thumb if the pellet rotated. The pellet did not rotate.

So if it didn’t rotate. Don’t that mean that the rifling sheared off some of the head of the pellet when I was loading? If so you would think that would kill accuracy.

Makes me wonder if using a pellet seater would really be the best way to seat the pellet once the head engages the rifling. Maybe something with a small diameter that you could push them in the center of the pellet inside the skirt.

That would be hard to do with the 300 though. Especially with a scope mounted but I guess a Allen wrench could be used with a point on it. The short end of the Allen wrench is what I mean.

I do believe I’m going to test that this week or weekend if I can’t during the week.

GF1,

What is it? 1:16? I do not think that anyone could feel that.

Chris U

If I can feel the difference in head diameter. I should feel a twist.

I know you don’t have any break barrels. But with a break barrel when you cock the gun and hold the muzzle end towards some light. Even on a cloudy day you can see the rifling very clearly.

The rifling is actually a pretty aggressive twist. So yes I do think I would feel the twist.

And on another note if the pellet was twisting when loading I shouldn’t feel as much engagement the whole distance the pellet travels as I’m loading.

Next time you got your springers out pay attention to how it feels when you load. Tell me what you think you feel. Seriously. I want to know what you think. And I do believe if you use a small sized Allen wrench with the short side of it with a point sharpened on it. You should be able to stick it in the center of the back of the pellet after you hand load just the head of the pellet. Then maybe make a red mark on the pellet and see if the mark moves as you push with the Allen wrench.

Heck would be the same as marking a line on your cleaning rod and see how many inches the rod moves for one rotation of the cleaning rod.

Point is. Maybe we are scuffing up the head of the pellet more than we think when we load it. And does that really affect acurracy as much as we think. Maybe the skirt being blown out and engaging be the riding is as important as well. Maybe the head size needs to be close to right to stabilize the front of the pellet. But maybe the skirt contact as it leaves the crown of the muzzle is what makes the big difference.

After all that’s what leaves the barrel last.

GF1,

On a 1:16 twist,… (360 degree turn in 16″), that would be 12.5 degrees in 1″ and 5.6 degrees in 1/4″. That would be tuff to pick up on. I am surprised that you are just now questioning this,.. with any air rifle. As for the rest of the thoughts,.. I guess that I would like to see a good fit with both the head and the skirt. The head is one thing,… the skirt will get blown out to conform to the barrel unless it is a super thick skirt. Just my 2 cents.

Chris U

All I can say is see before you speak. Then you can tell me something.

Means nothing right now till I get shown.

You never know what can be until you try all assumption now. And are you surprised I answered your comment that way. 😉

Opps,.. 22.5 degrees in 1″. BB!!!!!! we need some edit features up in here!!!! 🙂

Chris U

Well do you think you would see 22.5°?

GF1,

22 yes,… 5 most likely not. Still, that would be tuff even on a marked .177 pellet. Be sure to give us an update on your findings. Me?,… I will pass. Then again,… if you stumble upon some awesome finding,… I might consider. You have,.. after all,… gotten me to try some pretty off the wall stuff! 😉 Most of it worked too! 🙂

Chris U

My time to be a grasshopper.

Ain’t that what we do when we try and learn something new?

🙂

GF1,

You always have pushed all of the limits. Definitely inspired me to try a bunch of things.

Keep us posted,…. Chris U “over and out”,…..Zzzzzz,…. 3 AM comes early. (on 4 tens)

Chris U

I will say what I find for sure.

And 3 am. I been getting up at 3:45 am every morning since I started at this new place last October.

But I ain’t going to sleep yet. 😉

🙂

Chris U

Just tryed pushing the pellet with the pointed Allen wrench.

Did the .22 Tx and the .177 HW30s. Both guns no twisting rotation when I push the pellet after I engaged the rifling by hand. And I stopped before the skirt contacted the rifling.

But I also pulled the pellets back out from the way I loaded them. Both pellets from both guns showed rifling marks around the outside diameter of the head.

So what I am feeling is the head engaging the rifling when I load the pellets.

I guess all that means is I can tell by the feel when loading if it’s a good fitting pellet or not. Probably why I can tell if I get a looser pellet at a certain point in feel fit. That it might throw the shot a bit from the majority of the group.

Anyway done with that little experiment. 🙂

Hi Tom – I’m a journalist currently working on a story that involves airsoft. I’d love to talk to you for the story, but am not sure how best to get in touch with you. Would you be available to talk?

leah,

Welcome to the blog.

The last two journalists I gave interviews for were from the New York Times and the Washington Post. When the articles were published they were slanted away from what I had told them, and very anti-gun. So I don’t give interviews to the mainstream press anymore.

Sorry,

B.B.

Hi BB — I’m so sorry to hear you had a negative experience with media. My article won’t be for a mainstream site, in fact. Perhaps I could email you about the story I’m writing, and that might be helpful? I would actually love to have the knowledge of someone like yourself in the piece. If the answer is no, I understand. But I’d love the opportunity to explain a little further what I’m working on.

Thank you!

Leah,

Sure. Just contact me at

blogger@pyramydair.com

B.B.

Gunfun1,

Don’t own a break barrel myself, so I gotta ask. Does your barrel have a throat or other transitional area that the pellet is seated into? I’m thinking it is possible that might not see or feel any rifling twist when you seat the pellet, because the rifling has been gently machined away to allow the pellet to seat comfortably and predictably in the barrel, Or does the rifling start directly after the chamfer on the breech end?

No direct experience here, but most things I’ve read about prepping a barrel speak of a staging area that contains no rifling where the projectile is seating and waiting (the chamber / throat area for air guns). Then it goes to a transition area (the lead or leade) where the rifling slowly appears out of nowhere and starts gripping the projectile. As it grips the projectile, the projectile starts the spinning as it begins moving, and then it hits the full blown untouched rifling at so-many-turns-per-twist and goes out the end of the barrel.

Dave

Dave

There is a chamfer or lead in where the pellet is loaded. Probably about .015″-.020″. Looks to be about a 30° angle. So not very deep at all.

I would say that only about .020″ of the head of the pellet is in the bore before it contacts the rifling. And that’s on my HW30s. It’s the only break barrel that I own right now.

And that will probably be the gun I test the pellet push on. Much easier to see the center of the inside of the pellet skirt and to get my pointed Allen wrench centered and see the line marked on the pellet.

But still the point is. Maybe head engagement is important. But maybe also there is a balance of it and skirt engagement. And just like you talked about the chamfer were you loaded the pellet. It’s just as important if not more that the crown at the muzzle end of the barrel or exit chamfer is true and equal. And maybe head damage is not as critical as we think. Especially if the pellet does get scuffed up when loading.

My whole point is that head engagement at loading is important. But so is the balance of the skirt engagement. Then when the pellet exits things need to be true and right also. If that crown/chamfer is machined off center. What do you think will happen to the pellet when it exits?

And forgot.

Back to original thought. Soon as the pellet engages the rifling when loading it. And I stress the point. Loading the pellet.

Do we shear lead off the head of the pellet when we are pushing it in and fully seating it with our finger.

Maybe or finger or thumb is enough resistance on the back of the pellet to stop it from any rotational movement to cause shearing of the head.

Gunfun1,

According to what B.B. wrote in his Invention of Rifling series, if you assume a diablo shape for the projectile, then the skirt is embossed by the lands in the rifling, while the head receives little or no embossing at all. According to the image he included, the head simply rides on top of the rifling and makes slight contact as it is traveling through the barrel.

By implication, that means that you wouldn’t be shearing off any lead on the head of the pellet at loading time or at firing time unless one of two things is happening. The first would be a choked barrel, where the head of the projectile would also be embossed by the rifling at the last inch or two of its travel. The second would be if the head of the pellet was larger than the barrel machinist anticipated, and part of it is being sheared off to fit.

Here is a link to his article. The second graphic has a nice diagram and description:

/blog/2015/10/the-invention-of-rifling-part-3/

Dave

Dave

You know you made me think of something.

Did you see the report BB is doing on Geo791’s 34. Now that had a big open area the pellet set in when the pellets loaded. The whole pellet looks like it will fit in the barrel with the skirt flush before it contacts the barrel. To me hand seating the pellet in that barrel I would never be able to feel how the pellet loads. Which is something I pay very much attention to when I load. Most of the time it will tell me if the shot will fall right.

And no. As the pellet moves down the barrel and especially when hitting the smaller diameter choke the pellet is getting sized to the rifling.

My original thought is from hand loading the pellet. I think we could damage the head of a pellet more than we think when we load it.

Imagine if the pellet is cocked/angled a little bit when you load it. Maybe we hit one side of the pellet harder when it goes in the barrel. Then of course it naturally straightens out as you seat it fully in the barrel.

All in all we may be damaging a pellet when loading and we don’t even know it. I know this may sound crazy. But I load a pellet very gently. Matter of fact as gently as I apply the trigger when shooting. The more you feel how things work. The more you learn what could be wrong.

Gunfun1,

To your comment about head damage versus skirt damage, B.B. also wrote about it. In his What is Accuracy series, he describes a Dr. Mann who commissioned Harry Pope to built a one-of-a-kind barrel with threaded holes along its length. Dr. Mann could insert special pointed screws anywhere there was a hole and essentially damage the front of the bullet as it was fired. Didn’t make a bit of difference in accuracy. Damaged bullets grouped quite accurately.

What he DID find was that if he screwed up the BACK of the bullet, then they shot very erratically. If I’m reading your posts correctly, that’s where you’re concerned, right?

Here is a link to the article:

/blog/2016/08/what-is-accuracy-part-1/

Dave

Dave

I remember both articles very well. And yes that’s what I was getting at.

And to add one more thing that’s been talked about on the head and skirt fit.

There has been tests done on bent pellet skirts. And the pellets shot just as accurate not bent as well as bent skirts. But that was also with a PCP gun that had more of a air plastic that helped blow the skirt out and seal it.

I guess I shouldn’t of brought this subject back up. But it just seems that things get overlooked when we are trying to achieve accuracy. I was basically trying to say in a round about way that loading a pellet by hand could in fact in certian guns possibly cause acurracy problems.

Sorry phone.

Should say air blast. Not air plastic.

Gunfun1

Nah, I agree with you. One of the fascinating things to me is how much of our mutual passion ends up being an exercise in creating a Deming-like process for what we do that is definable, usable, and repeatable. It involves both hardware, procedures, and operations where your mortal enemy is variation. Anything you can do to eliminate variation is what you do only gets you closer to your goal. That kind of thinking is what used to excite me about my old Day Job in aerospace and defense.

And what’s our mutual goal? Trying to make pellets all through the same hole. I really like that goal.

Dave

Dlvoots,

Be careful,.. Ol’ Gunfun is prone to over thinking matters. I have fallen prey many times and the next thing you know,.. I am along for the ride. GF1 😉 In all seriousness though, he has been very innovative over the years and many things do pan out quite well. In truth,.. I have been known to do my own share of over thinking matters. 🙁

All in all,.. it is fun and we all learn a lot from the discussions.

Chris U

You mean we over think matters. I never realized that. 😉

🙂

Dang! That probably means I’m a kindred spirit with him. Gotta rethink my life choices now…

My own bad habit is over-explaining things. Guess it’s the Teacher inside of me going over to the dark side. The cliche’ goes something like this — I asked you what time it is, and you proceeded to tell me how the watch was built.

Worked for several years as a consultant to the shipyard in Newport News, and every time I’d lapse into my Bad Habit, the shipyard guys would quietly start saying “Tick Tock, Tick Tock, Tick Tock” to each other.

Actually, the real version was quite a bit spicier, but if Edith were still here, I would have instantly gone to Air Gun Jail for repeating it. 😉

Dave

Dave

I’m a machinist now for many years. Matter of fact when I started back to n the early 80’s we made projectiles and parts for the giuded missles. Then it turned to automotive.

So yep know what you mean about variables. And like you. I do like trying to find and eliminate them.

And like you say. Trying to get that pellet to fly in the same hole. Which is sometimes harder than it sounds. 🙂

Dave,

Let’s not forget Dr. Juran, either! 😉

B.B.

B.B. ,

Lord, I forgot about the dropping-the-pencil story! Thatt’s especially ironic, because when I used to teach around things like “tampering” with a system (i.e. making changes based on too few data points), I used to use sighting in a gun as the easiest example to explain it. Go figure (as in, It’s good to be humbled on a regular basis).

Dave

Dave

I did that pellet push with the pointed Allen wrench.

Read my reply above to Chris U.