by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

• The trigger

• Be careful!

• Adjustment is fine

• Lubrication

• The best thing you can do with a new airgun

• Final recommendation

• Summary

This report is written at the request of Jennifer Cooper Wylie, a follower on my Facebook page. A few days ago, she asked me to address this subject, and I thought it would make a wonderful report for all the people who are new to airguns.

This subject is large, so I’ve broken it into powerplants. Today, I’ll address spring-piston guns, only. So, when I say airgun today, I’m talking only about springers.

You have a new airgun. What can you do to make it better? Even if it isn’t brand new, you may be able to find a manual for your gun, and that’s where you should begin.

The trigger

You hear some people talk about polishing or stoning the sear in their airgun — is that something you should do? Definitely not!

I used to work on airguns at AirForce, and some of the trigger parts we made were case-hardened for long wear. Then, I sprayed them with a dry moly powder that was baked-on in an autoclave. If left alone, this coating will last the rest of your life. If you stone your sear, you risk removing all the moly particles, plus the thin shell of case-hardened material that will then expose the softer metal underneath. Then, your trigger will start to rapidly wear out!

Stoning refers to using an abrasive stone to smooth metal. It’s similar to sharpening a knife, only you aren’t putting an edge on the parts. If done correctly, it can turn a mediocre trigger-pull into one that’s fabulous. Unfortunately, about one person in a hundred knows how to do it right. The other 99 will do a botch job that runs the gamut from no change to a downright dangerous trigger that can slip off the sear by itself.

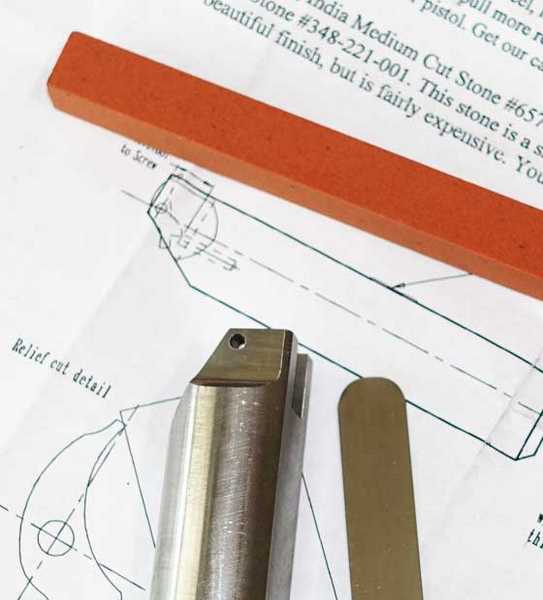

To correctly stone a sear or trigger requires precision jigs to hold the parts being stoned and sometimes even to limit what the stone can touch. Anyone who says they can stone a part by hand and eyeball it is in the 99 percent group that isn’t doing it right.

This is one-half of the tooling needed to stone the sear on a 1911 firearm. You don’t have to spend the $50 to buy this Ed Brown jig and feeler gauge, plus the several hundred more to get the hammer fixture with microscope to stone a 1911 sear and hammer; but you do have to be able to machine jigs like it that are just as accurate!

So, stoning is out, but there are things you can do. Lubrication comes to mind. I generally lube the engagement surfaces of the sear and trigger with moly-impregnated grease like Air Venturi Moly Metal-To-Metal Paste. This plates the surfaces with moly particles that don’t wear off — just like what AirForce does for their trigger parts.

Be careful!

Some spring guns, such as the Octane, have trigger pins that readily fall out. I can’t tell you how many people I’ve helped put their triggers back together when this happened. So, if you don’t know what you’re doing and cannot find instructions you can follow, leave the trigger lubrication alone.

Reader DTMoney wrote a guest blog that told readers how to properly assemble the Octane trigger. A lot of owners were losing the pins from the mechanism and not knowing where they went.

Some other triggers — such as the ones found on vintage BSF rifles — are made from steel plates that are sandwiched and then riveted together. They’re less than precise. These triggers are famous for wearing in and then wearing beyond the point of safety. They should not be lubricated with moly!

These sandwiched steel plates form the sear and trigger on most BSF spring guns. Don’t use moly on them!

Adjustment is fine

Some triggers allow adjustment. Some, like the Diana 27, can be adjusted to a razor’s edge of performance. Follow the directions, and your trigger should turn out well.

The T06 triggers Diana now installs on their rifles can also be adjusted very well, though not as fine as the old ball-bearing sears on the 27. Take the time to try the adjustments and see what you can do, rather than tearing into the mechanism and perhaps screwing things up.

Lubrication

If there’s anything that’s overdone on a spring gun today, it’s lubrication. That’s because piston seals and breech seals used to be made of leather and really did need frequent lubrication. But modern synthetic seals don’t, and it hurts the gun’s performance to over-lubricate.

A modern synthetic piston seal gets along fine with just a single drop of Silicone Chamber Oil every thousand shots. And if the gun has been lube-tuned, it might not even need that.

But what if you do own a gun with leather seals, such as an older Diana, BSF or even an older Daisy BB gun? They do need lots of frequent lubrication. For the guns that shoot below ~750 f.p.s., I recommend using household oil that contains petroleum. For the more powerful guns — and let’s face it, there are only a few — you want to use silicone chamber oil to keep the detonations down.

I oil such guns about once every couple months or if they haven’t be shot in a long time, I just oil before I shoot. Depending on the gun, I drop from 5 to 10 drops of oil down the air transfer port. Or, in the case of the Daisy, I remove the shot tube and drop the oil into the barrel jacket. Then, stand the gun muzzle up for about an hour before you begin shooting.

One last thing on lubrication that deals with the underlever and sidelever guns that have linkages and sliding compression chambers. I lubricate those joints and sliding chambers with Ballistol. It both lubricates and protects against rust.

The best thing you can do with a new airgun

I should have started the report with this. The best thing you can do with a spring airgun is just shoot it. And keep right on shooting it! Old El Gamo rifles were famous for being rough from the factory, then wearing into silky smoothness. Their crude triggers also wore into near perfection. Those who own an old one will know what I’m saying.

I bought a Beeman C1 brand-new in the early ’90s. That was a Webley breakbarrel spring gun. It was harsh, hard to cock and had a rough trigger right out of the box. After about 3,000 shots, though, that rifle slicked up into a very smooth-shooting airgun. It just seemed to get better and better the more it was shot.

My Beeman P1 pistol was detonating when it was new. A detonation is an explosion that sounds like a gunshot. I called Beeman, and service manager Don Walker told me to dry-fire the pistol a couple times. The P1 has a Teflon piston seal that needs to be squashed to fit the bore of the compression chamber, and dry-firing is how the Weihrauch factory does it. I did what he told me, and the gun hasn’t detonated since!

In the old Beeman catalogs, Robert Beeman told us that European spring guns wear in, not out. That lesson took a long time to sink in. After 40 years, I think I have it!

Just shoot the gun! Forget about tuning or lubricating it unless there’s a problem. And don’t look for a problem, either! It’ll find you if it’s real.

Final recommendation

Wipe your gun with a cloth that has Ballistol on it. Have enough on the cloth that it leaves a shiny surface after it has passed over the gun. Wipe the wood and metal parts. Even if the gun is older, a wipedown with Ballistol is a great rust prevention technique.

Summary

I know this probably isn’t what Jennifer Cooper Wylie was thinking when she asked for this series. Yes, there are things that other powerplants do need when they’re new. I just wanted to progress through the powerplants logically without missing anything, and spring-piston guns seemed the right place to begin.

Jennifer was looking for tuneup tips and possible modifications that owners can perform. I promise I’ll get to that in the future reports. But when it comes to spring-piston airguns, keep it simple and just shoot the guns!

Will have to wait till next week for what tips you have for CO2 and PCPs.

Tom,

This sounds so confusing that I wonder if it won’t discourage new air gun enthusiasts from taking the first step to purchase a new spring air gun.

Jim

I made my young daughter’s Daisy Powerline 35 better (for her) by shortening the buttstock with a chop saw (using a spray bottle for water cooling) and bonding a new 3D-printed buttpad to it. (See how nicely I segued into the 3D printing stuff I promised a couple of weeks ago! ;))

http://s1377.photobucket.com/user/calinb7/slideshow/Daisy%20Powerline%2035%20Buttpad

And video:

https://www.youtube.com/watch?v=L5ccXeflDLk

Here’s the Diana 34 piston seal. It took 18 minutes to print, Gunfun1. Also a photo of an extreme offset ring experiment:

http://s1377.photobucket.com/user/calinb7/slideshow/3D-Printed%20Air%20Rifle%20Parts

Video:

https://www.youtube.com/watch?v=h9a-mcEGXSk

The Taulman 618 nylon is too stiff, but would probably function. There are many softer and more flexible printing materials available nowadays, like urethanes and the new Taulman PCTPE. I think I’ll order some PCTPE.

B.B., Edith, Mike will have my cell phone number at the booth (#6010). I’ll probably be doing “research” myself on the floor but I will dash to meet you or rendezvous with you wherever you are stopping next. I know you will be very busy but I am looking forward to meeting you and I’d like to run a couple of airgun-related ideas past you.

-Cal

Cal,

Edie and I will look for you on day one. We are very busy, so we can’t stay long, but we will stop by.

B.B.

Thanks, B.B.! I know you two will be very busy and time is very short when attending SHOT. I am grateful for an opportunity to meet you and will keep our conversation brief. 12 miles of aisles is a lot of legwork–even if staying for all four days and there there’s always countless people to meet!.

Cal

Pretty cool. And I liked the video showing the printer working. Only thing videos don’t have a smell option. The printer doesn’t seem to be throwing off any smoke or fumes. Is there some sort of smell while the printer is working? Does it smell maybe like a hot glue gun working? Just curious but it definitely is a interesting piece of equipment.

I’m sorry that I haven’t had time to put together some better videos, Gunfun1. I’m pleased that you found them to be interesting.

The Taulman 618 nylon doesn’t have any odor. PLA filament smells sweet (it’s and ABS smells more like glue gun plastic (it smells like plastic), even though it’s not glue gun plastic. Usually the odors are not very strong. My family usually objects to the R2D2-like noises of the printer and closes the basement door! Sometimes you’ll see puffs of white water vapor coming off nylon when it prints, but I dry my filament in an oven and store it in a plastic bag with desiccant.

The videos show what is actually relatively slow printing (~ 25 mm to 40 mm per second) for nylon. I often print ABS or (even faster) PLA at over 100 mm / second! Nylon takes more time and cannot achieve the surface precision and resolution of PLA or even ABS, but it is usually stronger than the other materials and nylon parts suffer less from the possibility of delamination of the printed layers (what I call printed part “grain weakness.”)

It seems like there are new materials coming out every month for 3D printers. I checked and found several urethanes and other co-polymers that should work very well for piston seals. I will plan to order some new filament materials.

Cal

Ok this sounding like it could be a cool thing.

I would like to know how consistent the diameter of that seal is you printed.

Does it hold within .0011″. 001″.005″ or what when you use a micrometer or calipers or whatever to mic the diameter all around where it contacts the cylinder wall.

If it can’t produce that diameter correct the gun could be slow in velocity and not consistent. That will affect accuracy. If not true and round it won’t seal good. If to big it will be tight and slow the piston down. If loose the piston will slam and not produce good velocity because of the air blowing by the seal.

I would like to see at least 3 of them printed off that I could measure them. We got a cmm at work that I could write program for to measure them with.

They sure do look pretty but that means nothing if they aren’t consistently made to exact tolerances.

I guess the big question is how close to a given tolerance can the printer produce a part. And be repeatable. It ain’t all about just having a pretty face.

A simple small round part, like the seal, is pretty easy to dial-in to whatever dimensions you need. You usually need to iteratively revise the solid model though, and that makes it essential to have Solidworks, Geomagic, Spaceclaim, Fusion, or maybe Rhino (which I’ve never used). Solidworks is the gold standard, I think. Personally, I prefer sketch history based modelling but Spaceclaim is a direct editing style solid modelling program that seems to be getting popular. You can get-by with FreeCAD or OpenSCAD, just to get a feel for it, but it’s tough to do much design of any complexity with them.

For the seal, round is easy! Changes in plastic thickness is probably what most often causes dimensional errors. Without even trying, the printed seal is about +/- 0.001 in diameter (just using calipers). I could do better with a careful printer setup. It’s not like CNC machining though; it you wish to make parts where dimensions are important (instead of mere trinkets and garden gnomes) you’ll throw away a lot of plastic–even if you just download a mesh model that someone posted online for printing. A lot of development waste comes with the territory (and learning curve waste, initially) but, once you dial-in a part and its process, the results can be very repeatable! I would say under a thou repeatable with most plastics. Compared to a solid model, however dimensions are often off by several thou or even 0.10 plus in some cases. Z (height) is usually more precise than X/Y in fused filament fabrication printers, due to both the mechanical design of the machines and also how the plastic shrinks when cooling (height tends to not shrink). Most of what I do is prototyping or one-offs, though I have made a couple of small production parts that shipped with our products before we sprung for injection molds for them.

I designed all the plastic for http://www.smartfirearms.us/ and I printed fully functional prototypes of everything before going to injection molds. (I recently sold my half of the company to my business partner but will continue to work as and engineering contractor for him.) I did it all on an Ultimaker hobby printer and many people commented that my parts compared very favorable with Stratasys FDM printed parts and even SLA printed parts.

With an injection mold, if you follow good design rule and practices, the part will be within spec. With 3D-printing, you have iterate and to fudge the models quite often. Also, the limitations (injection mold design rules), and characteristics of the two processes are quite different and usually require substantially different solid models, but there’s nothing like holding a 3D printed part in your hand before spending big bucks (tens of thousands for dollars) on an injection mold. I’ve never had a “miss” when going to the mold, thanks to 3D printing.

Like I said previously, 3D printing isn’t like printing your family vacation photos. I think most of what has been published in the media constitutes hype (especially WRT guns) and the learning curve to make useful stuff is steep. I think I mentioned previously that the learning curve took more effort for me than learning how to run a mill or lathe, but I would hate to be without a 3D printer now!

Once I find a softer plastic that I like, I’ll try to get some seals to you. It will be awhile though, because I have a lot of projects in the works, ATM. If you decide to take the plunge, study what’s available on the market. There’s a lot of junk in the hobby realm that doesn’t work very well. If it were easy, you’d be able to buy a 3D printer at your local Apple store!

Sorry to co-opt your airguns blog, B.B. but, like many tools (including lathes and mills), 3D printers have a useful place in the air gun arena and gunsmithing in general and I thought I’d at least provide a little peek of what can be done with it for blog readers who might be interested.

Cal

Thanks for the information. And it sounds like a handful to get acquainted with the process. But from your explanation once the learning curve is over it could be very useful machine.

And no I don’t want to get into 3D printing its that I find them a interesting piece if technology.

And thanks for taking the time to explain more about the 3D printing. Maybe after the show you can do up a guest blog about the 3D printers. I don’t think Bb would mind.

Calinb,

Thanks very much for commenting on the 3D printing process, very interesting stuff!

Amazing what they can do with this process. A Chinese company has demonstrated the capabilities of its giant 3D printer by rapidly constructing 10 “houses” (garage size structures) in less than 24 hours. Built from predominantly recycled materials, these homes cost less than US$5,000 each.

Wonder how well this would work for making high precision ceramic parts for engines.

Calinb,

Very interesting slide show and video.

Another adhesive that may work for you might be 3M 847. It is a high temp adhesive used in the appliance industry to glue gaskets and seals to clothes dryer drums and bulkheads.

Check out the IZH 60/61 model air rifle. It is light, very easy to cock (side lever), accurate and has an adjustable stock. It is what I would call a semi bullpup configuration and is a really fun gun! Another one would be a QB58FC which is another side lever which I believe that you would enjoy and your daughter will grow into in a few years. The IZH shoots at 490 FPS and the QB58 in .177 cal. 750 FPS.

Bugbuster

B.B. What an excellent Blog ! Very timely ! And with the new UPS Billable Shipping weight, I would not like to ship my air gun to a tuner and add $60 or more to its total cost unless it was a very high end air rifle to begin with. That said ,like to add my ‘Thumbs Up’ on the two articles in my latest Shotgun News dated January 20. “The Airforce Texan” and “Pellet Comparison Test..are premium Pellets worth it” And, the other author’s 7 pages on the 2″ snubby revolvers..This is keeper which I seldom do.

Thanks, and best to you and Edith !

Pete

Orcutt, California.

Pete,

I’m glad you liked the articles. They cut the feature article way down. It had a lot more info plus 6 pictures that were not run.

I am very happy with that pellet article. That was based on the blogs I did.

B.B.

All,

So there I was yesterday afternoon, a bushy tail under the crosshairs, safety released, my finger on the trigger- and the air rifle discharged before I expected it to. The squirrel tumbled out of the tree. I was pleased with my shooting, but puzzled over the unexpectedly too-light-trigger-pull I had just experienced. My question was answered when I discovered the rifle would fire with the safety engaged. The rifle has an aftermarket sear installed by a guy whose probably in B.B.’s “other 90 percent.” I’ve shot the rifle a lot, and the trigger had worked fine, but I suspect the sear had been improperly filed to make it fit. This can all be repaired, but it was a field lesson in what B.B. wrote about this morning.

RB

RB,

We have holes in our walls and ceilings from sears like that. And by the way, I once adjusted a Sako Vixen .222 rifle that fired when I closed the bolt, so it isn’t just limited to airguns.

B.B.

Top tip for Weihrauch owners, get a free professional tune, how?…shoot 10’000 pellets through it, I’ve never had a Weihrauch that wasn’t utterly gorgeous after a couple of years shooting, bit twangy when new.

My 35 year old HW35 shoots better than a new one by yards 🙂

Dom,

Haven’t touched a thing on my HW50S, just shot it. Out of the box I was getting 1/2″ or so ten shot groups at 25yds. Now with 1000+ rounds shot I am shooting 3/8″ groups with the same pellets.

David

I have always been told that airguns are maintenance free(99%)! My first P-17 stated in the booklet enclosed to brake in the air gun would take between 4 & 5 thousand rounds threw the air gun! To brake in the barrel! Well I agree with the instructions in the booklet and this article! I have over 30,000 rounds threw it! Occasional pellgunoil! I had an air gun dealer I know very well! He had an air gunsmith in Oklahoma to tune my trigger! WOW! I shoot this P-17 most every day now! One hundred plus rounds everyday! Not counting the time I spend on shooting my air rifles! Thank you again for the articles and continuing education! I’ve been in and out of air guns for many years! Now with age I’m spending more time with the airguns,air gun blogs and gun shows! Instead of 6 to 7 days on the range? The driving range at the golf course! Semper fi!

J. Lee,

Isn’t it wonderful when something as cheap as a P17 turns out to be that good? I enjoy mine, as well.

B.B.

Thanks, I believe I’ll be investing in lead based on this news. 🙂

Matt61

BB- I followed your instructions re lubricating the trigger engagement surfaces with moly. My Diana 22 heavy trigger problem has been solved. Thanks for the information. Ed

Ed,

Thanks for the feedback. Isn’t it nice when something simple like that works?

B.N.

B.B.

With the 30 day no questions asked return policy of Pyramyd AIR best advice you gave is just shoot your new gun as much as you can. The new gun is either going to break in nicely or something will fail. All my springers shoot better today then they did out of the box.

David

Hi Tom,

I own a .177 Marauder and a .177 TX200. I really like PCP air guns and was thinking about buying my first .22 caliber air rifle. I’m having a difficult time deciding between the Hatsan AT44-10 Long QE and the Airforce Condor SS. Which do you prefer for reliability, power, accuracy, ease of operation, enjoyment, etc? If you could only own one of these two air guns which would you choose?

Thank you,

Doug

Doug,

Both rifles are powerful, but the CondorSS is more powerful. While its report is quieted, it isn’t as quiet as the Hatsan.

Both rifles are very accurate and both have nice triggers. The Hatsan is a repeater, and the AirForce allows you to change both calibers and barrel lengths in minutes.

Which set of features appeals to you the most?

B.B.

Hi BB,

I like the Condor a lot because it’s very light. I would probably not change the caliber or the barrel length. I like the Hatsan a lot because it’s a repeater and it’s very quiet.

Are they both reliable? Is one built better than the other or does one have fewer problems than the other? Is one more prone to leaking than the other?

Thank you,

Doug

Doug,

Both rifles are reliable and well made. The Hatsan hasn’t been around as long as AirForce, so their designs haven’t been tested by as many people, but I think either gun will suit you fine.

The AirForce rifle is both simpler (parts count) and more advanced (trigger and safety). I used to work for AirForce so I know a lot more about what goes into their guns, but I was impressed when I tested the Hatsan, too.

Maybe this will help. When I tested the CondorSS at 100 yards I shot a 10-shot one-inch group.

/blog/2013/07/airforce-condor-ss-precharged-air-rifle-part-7/

B.B.

Hi BB,

Which is the best pellet weight for .22 cal airguns this powerful….18.1 gr. or 21.1 gr. ?

Thank you,

Doug

Doug,

You would have to try both. It varies by gun.

B.B.

Ok, I thought that at those speeds, a heavier pellet would be best, as far as eliminating flyers and for greatest accuracy.

Thank you,

Doug

Tom,

When I saw the title of this blog the first thing that popped into my head was don’t mess with it. The rational was most people probably shouldn’t be tinkering with the inner workings of a new airgun (regardless of type). So I think you hit the nail on the head when you said to just shoot the gun and enjoy it.

J.

As BB quoted: European spring guns wear in, not out… I’ll second that for my FWB124 – so smooth after all these years.

A question about “making it better”…

We used to spray Dri-Slide (a Moly powder in a volatile carrier) into the freshly cleaned bore of a springer followed with a 3-in1 oiled patch to “prep” it before shooting.

Any thoughts on this practice?

Back then our “performance test” consisted in shooting the rifle just off vertically over the calm lake and use a stop-watch to time from firing to when the pellet hit the water. The owner of the gun with the longest time had bragging rights. Treated barrels (after a couple of shots to clear out the excess oil) did get better times.

Vana2,

Yes! DON’T DO IT!

Beeman found that the vehicle in Dri-Slide evaporates all protection on steel and it starts to rust immediately. I have seen this several times on my own guns. That’s why Dri-Slide was taken off the market by the old Beeman company.

B.B.

Hi B.B.

Agreed, the vehicle in the spray-moly cans is a strong solvent – that’s why I always followed a moly application with an oil chaser.

Now that you mention it, I don’t remember any cautions on the Dri-Slide brand can about applying oil after use.

The stuff I used (“borrowed” from my Father’s workshop) was a commercial grade spray that had instructions to wipe off any excess oil, apply moly and reapply oil. Dad explained that the moly has an affinity for and bonds directly to the metal so you would end up with distinct metal/moly/oil/moly/metal interfaces.

Evidently, the solvent is necessary to get through any oil film down to the metal where boundary lubricants such as molybdenum disulfide want to be.

Re-thinking it, I guess that my question should have been…

Should we prime a freshly cleaned “raw” metal bore with something like moly to fill the pores of the metal in an attempt to reduce friction or will this interfere with the normal (desired) leading of the bore and let the lead provide the lubrication?

Thanks

Vana2

This is one of the things that I like about airguns. To improve the trigger, shoot them. To clean them out, shoot them some more. I let Clint Fowler stone the trigger on my M1 Garand and that continues to work very well. Otherwise, it makes more sense to me to buy a gun that already has a good trigger. One reason I’m so intrigued by the Walther PPQ is that it’s supposed to have the best factory trigger of any 9mm auto.

Matt61

Vana2,

Yes! DON’T DO IT!

Beeman found that the vehicle in Dri-Slide evaporates all protection on steel and it starts to rust immediately. I have seen this several times on my own guns. That’s why Dri-Slide was taken off the market by the old Beeman company.

B.B.

Matt61,

A friend of mine just got the PPQ in .40 S&W. I had the opportunity to shoot a couple of mags through it at the range recently and was really impressed with the trigger. I had never even held it before, let alone fired it, and was amazed at the groups I got at 15 yds.

Jim M.

Noooo! I am happy for you and interested in this news, but I just learned that Walther is pulling almost all of its guns from California, including this one. So is Ruger. And you cannot get the SW M&P here either. Too much I say. I am unashamedly envious of you having access to the PPQ, but I need to switch my loyalties to the CZ line which is still available. The only weak point seems to be the trigger which gets us back to our blog post. I wonder how hard it is to have a gunsmith tune a trigger on a firearm handgun. Is it routine? Or are some models beyond tuning.

Matt61

Matt61,

Sorry for the long delay in replying. I have not shot any of the CZ pistols, but have heard good things about them. Trigger jobs are a “regular thing” in the shooting world. If you were a Government Model .45 shooter for example, there are any number of replacement triggers for those, and many excellent gunsmiths who specialize in trigger jobs. I’m sure you could find some IPSC or IDPA shooters in your area who could steer you to some reputable tuners.

Jim M.

B.B., you have my attention with the Ballistol. I’m always looking for a better “WD40” (By WD40 I mean an all purpose oil). None seem to do everything well and most don’t do much at all very good. Water seems to really kill them (I spray my kids bikes and most of the neighbor kid’s bicycles chains). Could this Ballistol be the holy grail I’ve been looking for? It sure sounds like it. I’m planning on buying some with my next PA order. One question, does it give off a strong “bad” odor? Don’t laugh, I can’t stand the smell of PB Blaster. Thanks again for a very good article. I’m so looking forward to pumps, CO2 and PCP care. Bradly

Bradly,

Ballistol DOES have an odor that many find offensive. It smells like fish. I have been told that is the anise in the product.

B.B.

B.B.,

Because of your recommendation, I ordered a can of Ballistol. I used it for the first time today, even applying some — lightly — to the stocks of my HW90 and RWS 54. Wow! That really made a difference. It worked great for taking care of fingerprints and skin oil on the metal parts, but really did an excellent job on the wood. Both of those rifles are fairly new, and the stocks are nice, but appeared somewhat dry, especially the HW90. I am sold on the Ballistol.

Jim M.

Jim M.,

I’m glad you like it.

B.B.

I would say that Ballistol is as close as you’ll get to the Holy Grail of preservative oils. Consider that it was used as a gun oil by the German army in both World Wars through horrendous environments. This is the group that knew enough to hang on to the Mauser 98k for half a century and who pioneered the assault rifle concept among many other innovations. They knew when to hold ’em and when to fold ’em, and if they used Ballistol that tells me what I need to know about the quality. Someone on the blog claimed to like the smell of Ballistol. I don’t, like most people, but it’s not a terrible smell either. And it would be worth a facemask for the benefits you get.

B.B., I wonder if there is yet another purpose to Ballistol. After cleaning up my Mosin and Mauser with Sweet’s 7.62 oil followed (after drying) by Hoppe’s #9 and drying again, I filled up the bores with Ballistol for storage, squirting it in from both ends. I imagine that the bore was completely filled up at some points. When I took out the guns for cleaning prior to a range visit, I pushed a new patch the through barrels and what came out the muzzle was this horrible blue toxic glop. Could it be that the Ballistol is working away and dissolving the copper and other residue that seems to have been baked in there during World War II? I hope so.

Matt61

BB, I think you have written about it in the past, but what is the difference between “silicone chamber oil” and regular silicone oil found in hardware stores?

Another question, this one off-topic, do you have plans to test the Hatsan Galatian PCP?

Off topic, to be sure, but, for me,, very relevant. I was wondering if it was feasible to shorten the rod in a nitro piston, in order to soften the recoil characteristics. My thought was to shorten it to the point that it no longer required a spring compressor to assemble.

Perhaps it would have been better to wait until you were writing about gas springs,, but as you may have noticed from my previous posts, my memory has it’s shortcomings,, and I might not have asked at all.

Edlee,

The solution to a softer shot cycle is not a shorter stroke, but lower gas pressure in the unit. Crosman achieved this wit the Benjamin Legacy that’s no longer made and also, to a lesser extent, with the Lower Velocity Nitro Pistons.

In fact it is my contention that a low-pressure gas spring wiuth an extra-long stroke would be an ideal spring gun!

B.B.

My memory isn’t what it used to be (heck it never was) but didn’t Beeman used to have a gas ram pellet rifle that the power could be “adjusted”?

Bradly,

Yes, the Beeman Crow magnum is a Theoben Eliminator and the owner could change the pressure in the gas spring.

B.B.

Could you suggest a lower velocity nitro spring that would fit a trail NP? Since I live in PA, and hunting with air rifles is not legal,, I would love to be able to use this rifle for paper punching, and possibly field target. I don’t think that I need the maximum velocities for either of those,, but a more pleasant cycle would be nice.

ed

Any info on an old underlever daisy pistol, the model 188? Value, quirks? Just found one, flea market deal, $10.00

Hey, it is a spring gun, worth about 30 bucks, made from the late 70s till changed to plastic then discontinued mid 90s. First made to take pellets then just bbs, mines the later, though a little trim on the loading view port it could easily be made to shoot pellets, the power is low, probably not worth it. I think the design is amazing! Why is it discontinued? Someone should bring it back, all metal and packing a punch! It would probably keep up with the beeman p series, easier loading, solid design… hmmmm

RDNA,

All I can say is look it up in the Blue Book. The 188 was never popular when available. It is grossly underpowered and they didn’t last very long.

B.B.

Im sure with pellets it won’t be anything crazy but can tell you it dents a sardine can like 400fps co2 normally does. Going to chrony it tomorrow, it seems to be well taken care of, 100%. The design is what piqued my interest, it could be a powerful gun and all metal could hold up, but not only that the ergonomics are perfect, more comfortable then the 1377. Could you test one? I think its a seriously underrated lost treasure.

RDNA,

Since you have one and you have a chronograph, why don’t you do the test!

B.b.

It appears that someone left their Winchester 1882 or 83 leaning against a tree some years ago, perhaps 50 to 100 years ago, no one knows for sure but this is not the way to make your rifle shoot better.

http://www.bbc.com/news/world-us-canada-30855782

So glad to read it won’t be moved, that’s exactly what I was thinking by the end of the article, that better not be moved.. very cool story, to know what happened to the owner! Was it a kid lost it? A shootout? Guy fell down a ravine, trampled by cattle? Just crapped out (disentery) in the field working? Thanks foe sharing, what a mystery!

Hi BB

I know you are enjoying the shot show!

I love FWB rifles. I plan to get another PCP and I have drawn a bead on the only FWB PCP I can just barely afford a FWB 500. I have googled for info and reviews on this gun but turned up nothing but bland descriptions. Pyramyd AIR sells them. Is it possible that they can loan you one to review?

Thanks

Ton,

I will look into it.

B.B.

B.B.,

You replied to my post in another thread recently — about sighting in distances for my RWS 54 — and I forgot to thank you. So, thank you for the good info.

I know this article is about springers, but I have a new HW90. I’ve had it about 5 weeks, and have been shooting it as much as I can in my basement 10m range. At first it seemed great, but then all of a sudden stopped grouping well. I remembered reading about other rifles that needed the stock screws tightened. I checked, and the two forestock screws were loose. I tightened those and it seemed to help. I checked for other loose screws and the rear trigger guard screw was also loose. I had reason to call Pyramyd AIR about something else, and ended up on the phone with tech support. They suggested I Blue Loctite all four stock screws — the two forestock, and the two trigger guard screws. I have not yet done so, and would like your opinion on that. They also suggested I clean the barrel with something like Simple Green, and lube it with one drop of non-petroleum lube, which I did. I have put about 75 rounds through it since doing so.

I just scoped the Weihrauch with a UTG scope and am really having trouble getting consistent groups now, with pellets that shot well before, and am trying to figure out if I have over-tightened that rear trigger guard screw, or if the HW 90 is much more hold sensitive than I realized and now maybe I’ve changed my hold too much and can’t figure out what I was doing right before. Any advice or suggestions for things to trouble shoot would be appreciated.

Thank you!

Jim M.

Jim M.,

First of all, the HW 90 is a springer. It just uses a gas spring instead of a steel one. So when it comes to things like functioning and hold sensitivity, it acts the same as any other springer.

I doubt that tightening the stock springs is the problem. You need tight screw for a consistent shot with a springer. And blue Loctie is the industry standard for screw threads.

But cleaning the barrel with Simple Green is something I have never heard of. I always used JB Non-Embedding Bore Cleaning Compound on a brass or bronze brush. 20 strokes of the brush with the compound in each direction will do it. Then clean the residue out of the barrel with dry patches.

I think your hold is the real problem, though. Gas springs are just as sensitive to hold as steel springs. Anjd as soon as possible you need to get so real distance for your rifle. 10 meters is too close to tell anything. You need at least 25 yards and 35 would be better. I know the weather is probably keeping you inside, so now is the time to n find those one or two good pellets and get ready for longer distances. And to perfect your artillery hold.

B.B.

B.B.,

I appreciate the advice. I still haven’t had time to get out where I could shoot longer distances, but have worked on my hold a little and it seems that is probably most of it. After scoping the Weihrauch I had been trying to shoot off a different kind of rest than before. Yesterday and today I’ve only had a little time to shoot so I just went with Crosman HPs and shot offhand. I am not seeing the wild shots that way, although I can see I’ll need work to tighten those groups. It’s way more hold sensitive than I had realized – moreso than my Umarex Octane, I believe Also, I think there is a little parallax issue. I put a monster scope on it — UTG 4-16 x 56. Bigger is better, right? Ha! 10m is way too short a distance for that thing.

Thanks again. Looking forward to reading your reports about the SHOT show.

Jim M.

Well, it sounded like the angiogram told nothing but good news!

Your brain is doing exactly what it’s supposed to do, keep yourself hydrated and stay on your bloodthinners. Get plenty of physical activity and have patience. There was a slight restriction where one artery branches into about 4 but blood supply has already started routing around it. There were cobweb-like capillaries everywhere!”This is not normal”,”Normally none of this would be happening yet”. There’s nothing I can do that I wouldn’t consider to be more detrimental than beneficial. One thing we can do is raise your bloodpressure to what we call “permissive hypertension” to expand their growth.

I’d feel all better if I didn’t hurt so much. Now it’s time to get started on my back!

Reb

OK, reading about Ballistol on their web site, I’m wondering if it would be go for CO2 guns? This is on their site: “Increases performance of CO2 model airplane motors”. ?

B.B.

When this series is complete it will be a great reference for us to use to keep the use of lubes straight.With all different kinds of guns ,pcp pumps and all, it is hard to be sure I’m remembering correctly since I may not use a type of gun for a while.

On another note;P.A.has two new kids on the big bore block.The Carnivore .30cal.and the .357cal. I always wanted a recluse in .357 but it is too noisy.I feel more inclined to the .30cal here though and a 3 for loudness might work for me.Was I sleeping or have you ever tested a Hatsan pcp?Do you think you’d be interested in testing one of these?I’d like to see what the .30cal. would do in your hands.With one pellet choice so far, it either groups or it doesn’t.And it either fires at about 860fps or it doesn’t,no muckin’ around with pellets.-Tin Can Man-

Tin Can Man,

I have tested several Hatsan PCPs. The last was the AT44-10 Long QE.

Before that I tested several Hatsan single shots that were branded with other names like Gamo, etc.

B.B.

Hi BB,

I had read your article on making a sound box, and since I recently moved to an apartment, I decided to try it. I have room for a 10m range shooting from just inside the front door to the back end of the spare bedroom. I can shoot the HW30s and the X20s inside with no problems, but I wanted to see if I could shoot the Benjamin 392 inside without making a lot of noise, and if so, I can think about getting a Discovery.

I attached a link to a photo of it I uploaded to photo bucket. Short version, it works great. I can shoot the 392 at 8 pumps thru the box, and it sounds as if I am shooting it outside with only 1 pump. I am hoping if I get a Discovery that I will be able to use it inside when I cant take it to the range.

Its 20″ square, and 30″ long. I used white foam poster board(6 sheets) to make the box. I used packing tape to hold it together on the outside and used a hot melt glue gun on the inside. I got 2 cheap $10 foam mattress pads at walmart and hot melt glued it to the inside, all surfaces. I also hung a couple of rags from the top to act as sort of baffles. The shooting hole is 4″ by 7″. I put the muzzle inside about 8 inches and that’s all it needs. I also picked up a $5 grey blanket at Walmart and just draped that over the top and sides as an extra sound barrier. It cost me about $40 total, including the hot melt glue gun, and glue sticks.

One caution, that hot glue is really hot. When it gets on you it burns like……well it really hot! 🙂

http://s143.photobucket.com/user/jimaok/media/SoundBox1-1.jpg.html?filters%5Buser%5D=34898020&filters%5Brecent%5D=1&sort=1&o=0

Jim,

Welcome to the blog. You are the only person to try my box and give any feedback. I see your box and it looks great. It’s a little difficult to get it set to the correct height, but once it’s there you can leave it alone.

Thanks for the feedback. I have seen this idea work for big bore airguns shot indoors, so I knew how well it worked.

B.B.

BB,

Wanted to let you know that my Diana 350 Magnum arrived and I adjusted the trigger just as you suggested. It shoots great as long as I hold it loose. Still working on the hold…got 1 inch groups at about 20 yards for this first attempt after I got settled. Looking for a scope now… any opinion on Hawke vs Leapers for this gun? Safe travels…much appreciation for all you and Edith do!

Paul