*Offer expires 04/30/24 at 3 a.m. ET. Some exclusions apply.

*Offer expires 04/30/24 at 3 a.m. ET. Some exclusions apply.

On this TX 200 spring rifle from Air Arms, there are two parallel dovetail grooves with three scope stop holes between them. Select one of these three holes for the scope stop pin on the rear mount (or if you use a one-piece mount, put the pin at the rear) to engage. |

Two-piece scope rings give more flexibility when positioning on the airgun. They are equally strong, rigid and true as one-piece rings. |

One-piece scope rings have the same features as two-piece rings, but they are heavier. Some shooters prefer them to two-piece rings. |

The rings are mounted on the rifle minus their top caps. The scope is laid in them for positioning. |

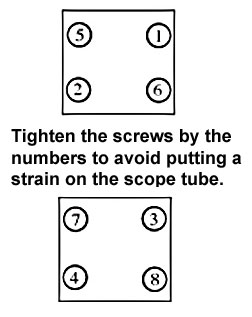

Once the position of the scope is determined, the rings are tightened to the gun and the top caps are installed. Center the vertical reticle before tightening the caps. |

|

Buy With Confidence

Get FREE shipping on qualifying orders! Any order $150+ with a shipping address in the contiguous US will receive the option for free ground shipping on items sold & shipped by Pyramyd AIR during checkout. Certain restrictions apply.

Free shipping may not be combined with a coupon unless stated otherwise.

View Shipping Info

We work hard to get all orders placed by 12 pm EST out the door within 24 hours on weekdays

because we know how excited you are to receive your order.

Weekends and holiday shipping times will vary.

During busy holidays, we step our efforts to ship all orders as fast as possible,

but you may experience an additional 1-2 day delay before your order ships.

This may also happen if you change your order during processing.

View Shipping Times

It's important to know that due to state and local laws, there are certain restrictions for various products.

It's up to you to research and comply with the laws in your state, county, and city.

If you live in a state or city where air guns are treated as firearms you may be able to take advantage of our FFL special program.

U.S. federal law requires that all airsoft guns are sold with a 1/4-inch blaze orange muzzle

or an orange flash hider to avoid the guns being mistaken for firearms.

View Shipping Restrictions

Get the most out of your equipment when you work with the expert technicians at Pyramyd AIR. With over 25 years of combined experience, we offer a range of comprehensive in-house services tailored to kickstart your next adventure.

If you're picking up a new air gun, our team can test and tune the equipment before it leaves the warehouse. We can even set up an optic or other equipment so you can get out shooting without the hassle. For bowhunters, our certified master bow technicians provide services such as assembly, optics zeroing, and full equipment setup, which can maximize the potential of your purchase.

By leveraging our expertise and precision, we ensure that your equipment is finely tuned to meet your specific needs and get you ready for your outdoor pursuits. So look out for our services when shopping for something new, and let our experts help you get the most from your outdoor adventures.

View Service Info

Shop and purchase with confidence knowing that all of our air guns (except airsoft) are protected

by a minimum 1-year manufacturer's warranty from the date of purchase unless otherwise noted on the product page.

A warranty is provided by each manufacturer to ensure that your product is free of defect in both materials and workmanship.

View Warranty Details

Didn't get what you wanted or have a problem? We understand that sometimes things aren't right and our team is serious about resolving these issues quickly. We can often help you fix small to medium issues over the phone or email.

If you need to return an item please read our return policy.

Learn About Returns

Get FREE shipping on qualifying orders! Any order $150+ with a shipping address in the contiguous US will receive the option for free ground shipping on items sold & shipped by Pyramyd AIR during checkout. Certain restrictions apply.

Free shipping may not be combined with a coupon unless stated otherwise.

View Shipping Info

Want More?

Join Our Email List for News and Deals!

Join the Pyramyd AIR mailing list: Our e-mails are filled with new products, deals, sneak peeks, tips and tricks, contests and more - sign up today!

Text JOIN to 91256 and get $10 OFF Your Next $50+ Order!

* By providing your number above, you agree to receive recurring autodialed marketing text msgs (e.g. cart reminders) to the mobile number used at opt-in from Pyramyd AIR on 91256. Reply with birthday MM/DD/YYYY to verify legal age of 18+ in order to receive texts. Consent is not a condition of purchase. Msg frequency may vary. Msg & data rates may apply. Reply HELP for help and STOP to cancel. See Terms and Conditions & Privacy Policy.